-

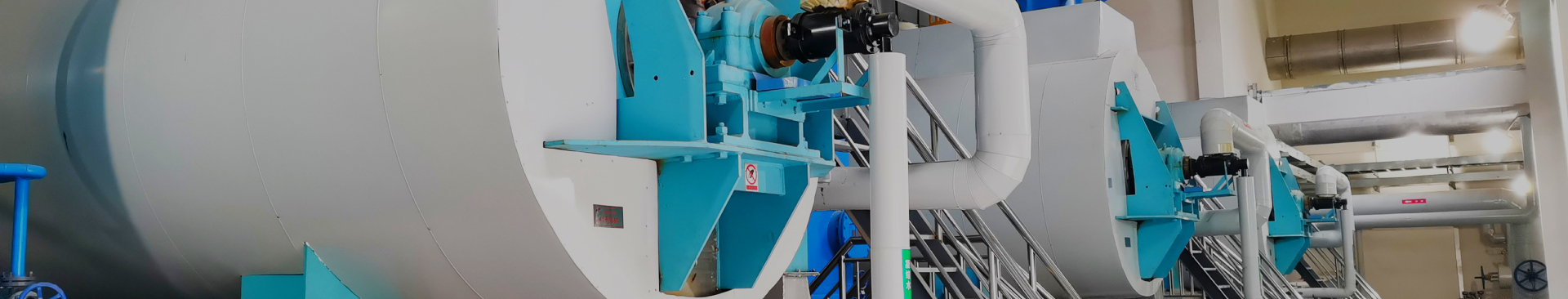

Sludge Drying

-

Thermal Power Plant/ Refuse Power Plant Collaborative Disposal Process

-

Drying Incineration Process

-

Cement Kiln Collaborative Disposal Process

Cement Kiln Collaborative Disposal Process

Wet sludge is transported by a sludge

truck to the wet sludge silo, and then

pumped into the dryer. The exhaust

steam from AQC or SP boiler or back-

pressure steam turbine is used as

the heat source for the dryer. The wet

sludge is quantitatively fed into the

dryer, and is stirred and fipped by the

slow rotation of the disc to constantly

update the heating interface and fully

exchange heat with the heated body and disc, so that the surface moisture in

the sludge evaporates. At the same time, the sludge is pushed towards the

outlet by the guiding mechanism during transportation, and is continuously

stirred to ensure complete drying. The dried sludge is discharged from the

outlet and transported as auxiliary fuel to the cement rotary kin for

incineration disposal.