- Technical Parameters

- Working Principle

- Equipment advantages

- Parameters

- Principle

- Advantages

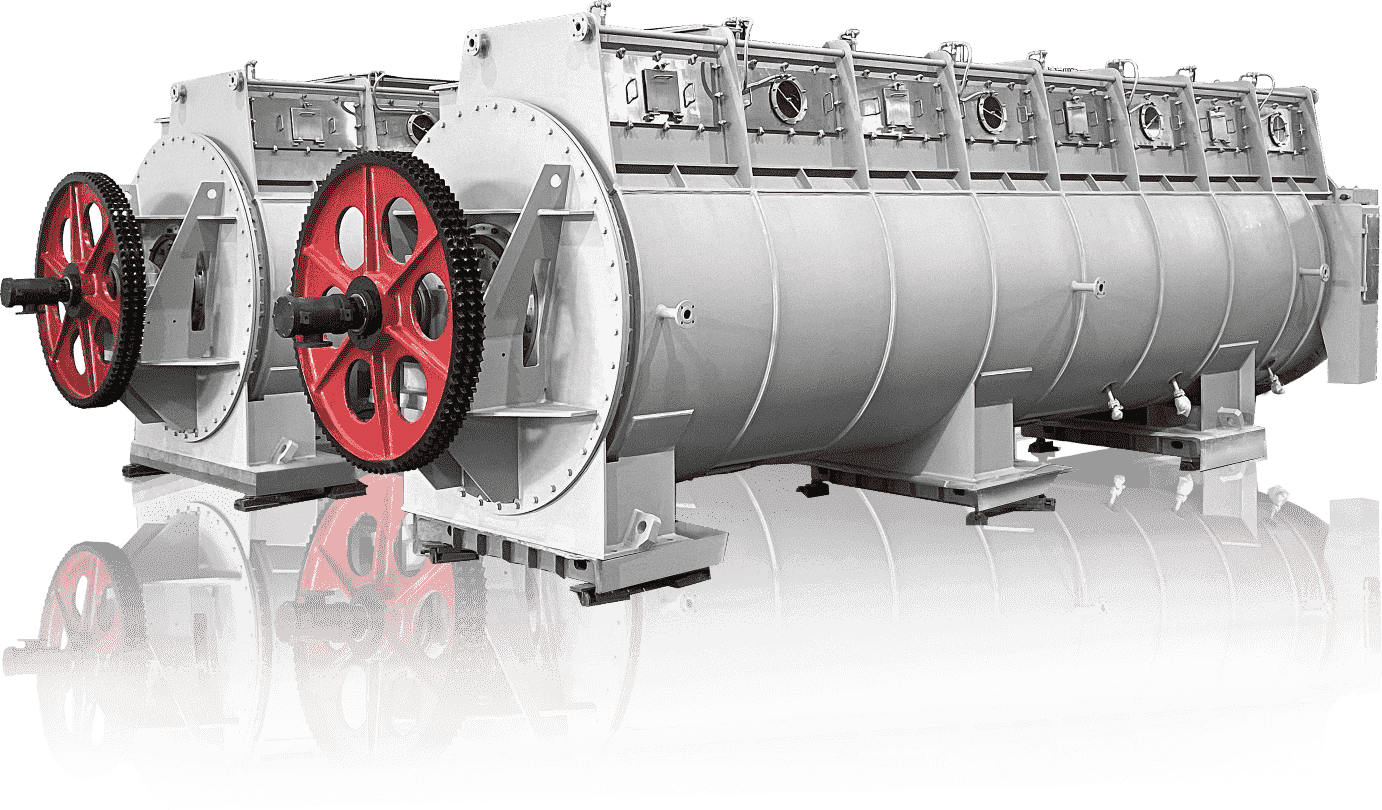

SDK Series Super Disc Dryer

| Model SDK | Power(KW) | Boundary Dimension L*W*H (mm) |

|---|---|---|

| 60 series | 15 | 5200*1900*2700 |

| 85 series | 22 | 6400*1900*2700 |

| 130 series | 45 | 6200*2500*3000 |

| 170 series | 45 | 7500*2500*3000 |

| 210 series | 55 | 9000*2500*3000 |

| 240 series | 75 | 8600*2800*3300 |

| 280 series | 75 | 10100*2800*3300 |

| 370 series | 90 | 10700*3000*3650 |

| 450 series | 110 | 12100*3000*3750 |

| 550 series | 160 | 12860*3760*4150 |

FDK Series Disc Dryer

| Model SDK | Power(KW) | Boundary Dimension L*W*H (mm) |

|---|---|---|

| 1 | 5.5 | 3450*1150*1750 |

| 2 | 7.5 | 4000*1850*1750 |

| 3 | 11 | 4700*2000*1600 |

| 4 | 15 | 4800*2350*1850 |

| 5 | 15 | 5650*2250*1600 |

| 6 | 18.5 | 5200*2750*2250 |

| 7 | 30 | 5900*2850*2350 |

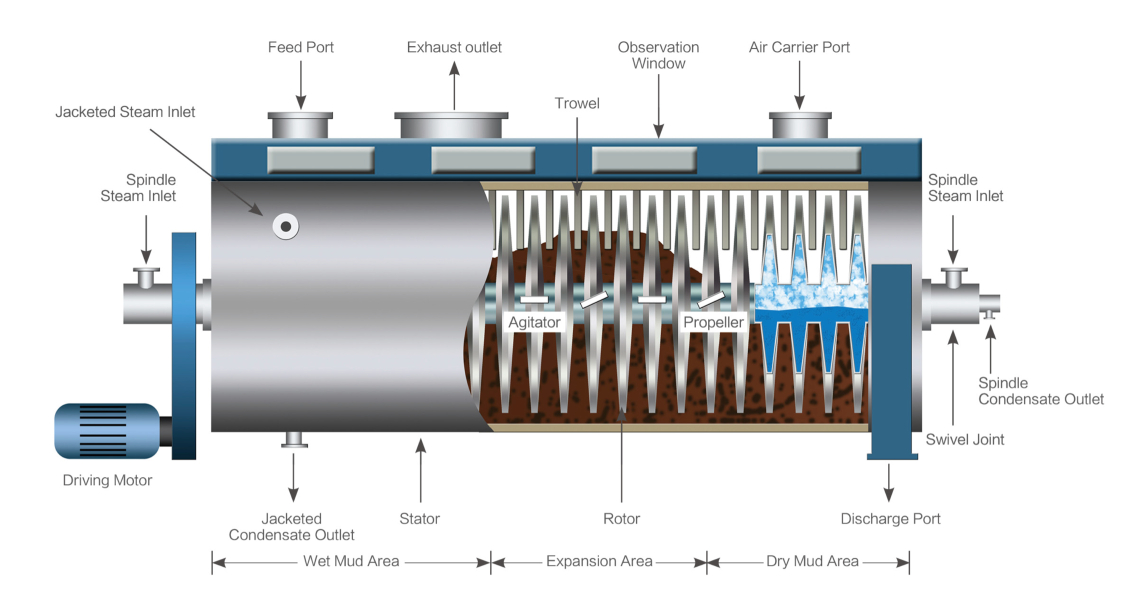

The material is fed into the dryer by the feed port. The working medium flows between the shell and the hollow shaft and transmits heat through the jacket, the hollow shaft, and the hollow plate welded on the shaft. The material is heated and dried indirectly; the steam produced is gathered in the dome of the dryer and is taken out of the dryer by gas. The hollow plate is completely perpendicular to the shaft,and there is no cutting of the material. The material is stirred by the propeller/agitator on the edge of the plate, and the drying surface is constantly updated to achieve the purpose of drying.