-

Coal Sludge Drying Process

-

Fish Meal Drying Process

Fish Meal Drying Process

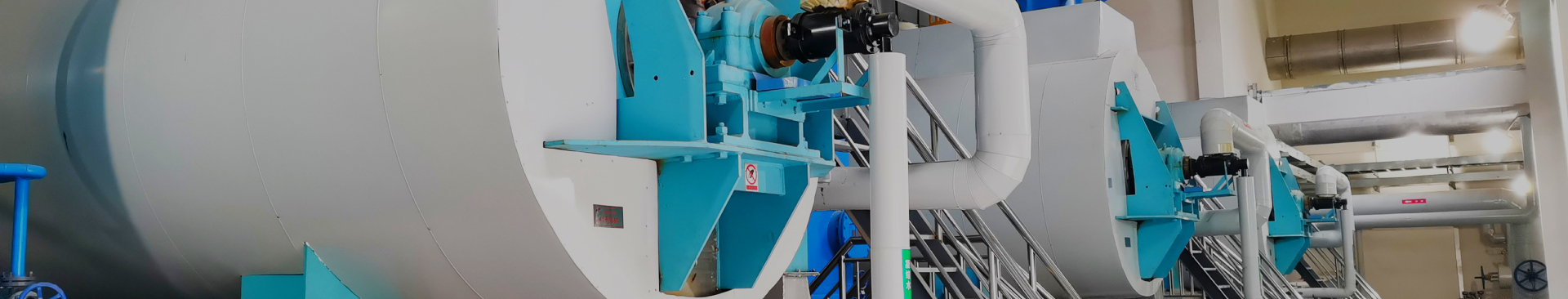

The fish meal dryer is a device that uses a heat source (usually steam) to

dry the solids produced during the steaming process to obtain fish meal.

The processing of fish meal generally goes through processes such as

steaming, pressing, separation, drying, and grinding. One or more types of

fish are usually used as raw materials for processing, such as raw fish,

fish filets, and scraps. After being separated by a magnetic separation

device, they enter the hopper and are continuously fed into the cooking

machine through a screw conveyor. After cooking, the material enters the

press directly, and after being pressed by the twin screw, the press juice

enters the juice pool, and the press residue enters the dryer. The protein

water is concentrated and added to the dryer for drying together. The

squeezed juice is preliminarily precipitated and then sent to the heating

tank. After being heated to a certain temperature, it is sent to a

three-phase horizontal screw centrifuge to separate the fish residue and

fish juice. The fish residue is recovered into the dryer, and the fish juice

is sent to a disc separator for oil-water separation. The fish oil is

obtained through further processing to obtain the finished product fish oil.