BLOG

Your Premier Fish Meal, Animal and Poultry by-products Drying Solution

Your Premier Fish Meal, Animal and Poultry by-products Drying Solution

02 January 2024

The TIC Technology’s disc dryer is the ideal solution for removing as much water as possible from coarser fish, animal or poultry by-products gently.

Take fish meal for detailed introduction.

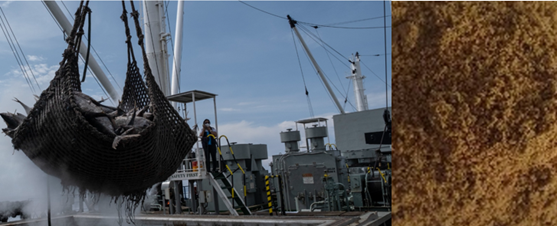

Fish meal is a commercial product made from whole wild-caught fish, bycatch, and fish by-products to feed farm animals, e.g., pigs, poultry, and farmed fish. Because it is calorically dense and cheap to produce, fishmeal has played a critical role in the growth of factory farms and the number of farm animals it is possible to breed and feed.

Fishmeal takes the form of powder or cake. This form is obtained by drying the fish or fish trimmings, and then grinding it. If the fish used is a fatty fish it is first pressed to extract most of the fish oil.

Fish meal drying is a crucial process, enhancing its shelf life, preserving nutritional integrity, and ensuring a consistent, high-quality product. This pivotal step not only optimizes storage and transportation but also contributes to the overall efficiency and sustainability of industries such as aquaculture and animal feed, where fish meal serves as a vital component. In essence, fish meal drying plays a pivotal role in maintaining product quality, meeting industry standards, and supporting the global demand for nutritious and sustainable feed ingredients.

Fishing Industry

In the dynamic landscape of fish meal manufacturing, TIC Technology stands as a beacon of expertise and innovation. As a professional drying manufacturer, we specialize in providing cutting-edge solutions that elevate the efficiency and quality of fish meal production.

Our commitment to excellence is reflected in the advanced technology integrated into our drying systems. From the moment raw materials enter our machines through the inlet, a meticulous process unfolds. The working medium flows strategically between the shell and hollow shaft, ensuring optimal heat transfer. The use of jackets, hollow shafts, and welded hollow disc plates on the shaft guarantees the indirect heating and precise drying of materials.

TIC’s fish meal dryer is a device with heat source (usually steam) to dry the solid residues from the cooking process in fish meal production, obtaining the final fish meal product.

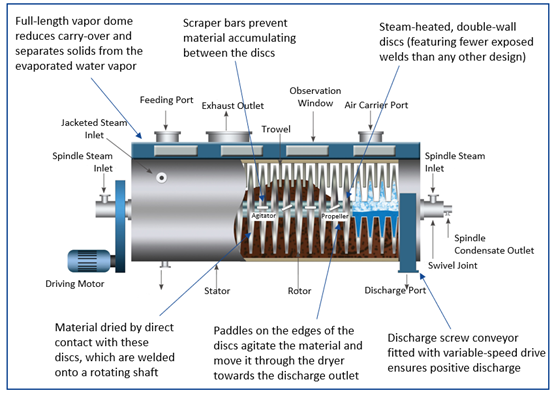

Here is the sturdy structure:

Stator:

the stator shape of disc dryer is approximately cylindrical with dome structure, providing volume space for carrier gas and steam. The dryer is also equipped with exhaust gas outlet and inspection port for maintenance and inspection. The stator end plate is flange- mounted for easy maintenance, and it is also used for fixing the bearings of the rotor.

Rotor:

the bearing part of the whole disc dryer, consists of a hollow shaft and a set of hollow discs. In order to improve the firmness of the disc, several sets of supporting rods are arranged in the hollow cavity. The outer edge of the disc is equipped with a propeller/agitator, which simultaneously plays the role of pushing and agitate the material.

Driving device:

consists of embedded reducer, belt drive, coupler and motor, used to drive the rotors rotation gently.

Structure of Disc Dryer

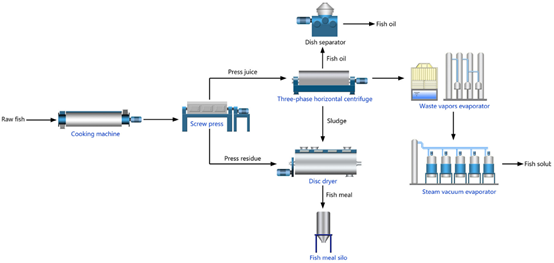

The processing of fish meal typically involves many steps, such as cooking, pressing, separation, drying, and grinding. It usually utilizes one or more types of fish as raw materials, including raw fish, fish fillets, and by-products. After iron removal with magnetic separation equipment, the material enters the hopper and is continuously fed into the cooking machine via a screw conveyor. After cooking, the material enters the press directly, undergoes pressing by twin screws, with the pressed juice entering the juice tank and the pressed cake entering the disc dryer. The concentrated protein water is added to the disc dryer for drying. The pressed juice undergoes preliminary settling, is then sent to the heating tank, heated to a certain temperature, and further processed in a three-phase horizontal screw centrifuge to separate fish solids and fish liquid. The fish solids are returned to the disc dryer, and the fish liquid is sent to a disc-type separator for oil-water separation. The separated fish oil undergoes further processing to obtain the final fish oil product.

Fish Meal Drying Process

As the material undergoes the drying journey, the generated steam is efficiently gathered at the apex of the drying machine and carried away by the carrier gas. This not only enhances the overall efficiency of the process but also emphasizes our commitment to sustainable and eco-friendly solutions.

At TIC Technology, we understand the critical role fish meal plays in various industries, from aquaculture to animal feed. Our drying solutions are designed not just to meet but exceed industry standards, ensuring that your production processes are optimized for success.

Choose TIC Technology for reliability, innovation, and a commitment to delivering excellence in fish meal drying. Join us on the forefront of technological advancements and elevate your production capabilities with our state-of-the-art drying solutions.

As a professional disc dryer manufacturer and drying solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to tic@tdgtic.com.