BLOG

What is Sludge Drying and Incineration?

What is Sludge Drying and Incineration?

13 September 2023

In the world of wastewater treatment and waste management, sludge poses a significant challenge. Sludge, the semi-solid residue left behind after the treatment process, contains water and various organic and inorganic materials. To address this challenge, sludge drying and incineration have emerged as effective and sustainable solutions. In this blog post, we will explore what sludge drying and incineration are, how they work, and why they play a crucial role in modern waste management practices.

What Is Sludge Drying and Incineration?

Sludge Drying: Sludge drying is a process that reduces the moisture content in sludge, transforming it into a more manageable and less bulky material. By removing excess water, sludge drying not only reduces the volume of sludge but also makes it suitable for various disposal or reuse methods.

Incineration: Sludge incineration is the controlled burning of dried sludge in specialized facilities known as sludge incinerators. This process involves subjecting the dried sludge to high temperatures, typically in the range of 850 to 1,200 degrees Celsius (1,562 to 2,192 degrees Fahrenheit), to convert it into ash, gas, and heat energy. The heat generated during incineration can be harnessed for electricity or steam production.

How Does Sludge Drying and Incineration Work?

Sludge Drying:

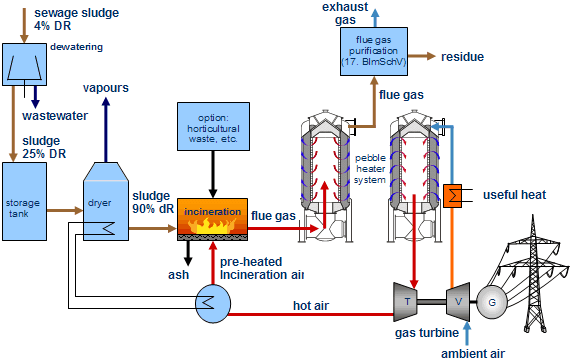

1. Dewatering: Initially, sludge undergoes mechanical dewatering processes to remove as much water as possible, reducing its moisture content.

2. Drying: The partially dewatered sludge is then subjected to thermal drying methods, such as direct drying (hot air), indirect drying (conductive or convective heat transfer), or solar drying. These processes evaporate the remaining moisture, leaving behind dried sludge.

Incineration:

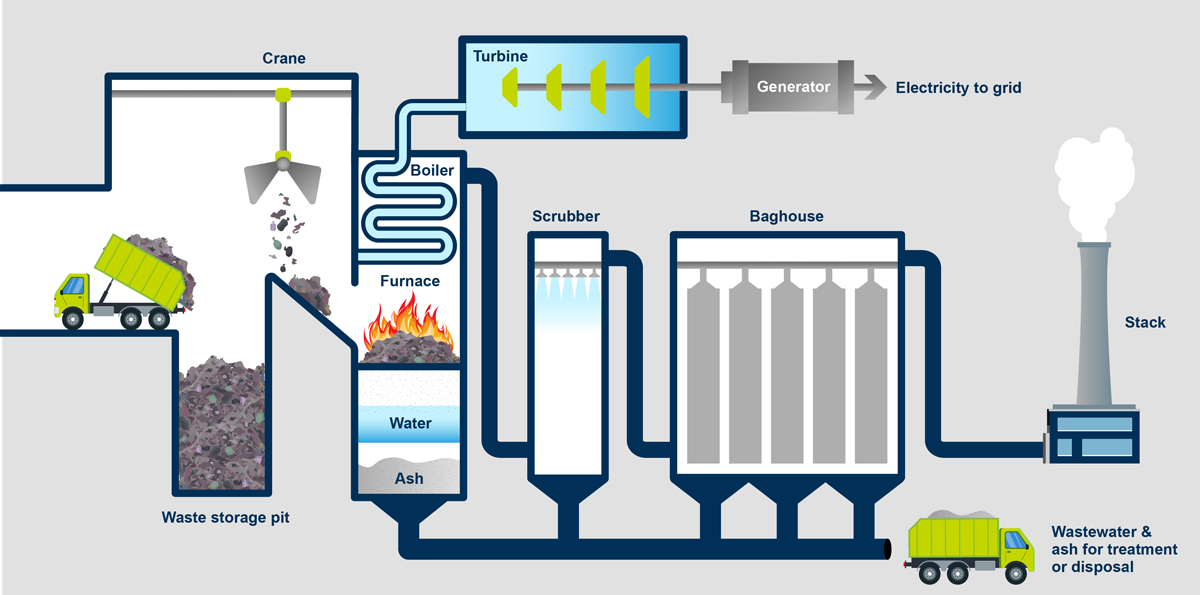

1. Preparation: Dried sludge is fed into a sludge incinerator, where it is combusted.

2. Combustion: High temperatures are applied to the sludge, causing it to burn and break down into its constituent components: ash, gases (carbon dioxide and water vapor), and heat energy.

3. Energy Recovery: The heat energy produced during incineration can be captured and used to generate electricity or provide heat for industrial processes, making it an energy-efficient waste-to-energy solution.

Why Are Sludge Drying and Incineration Important?

Sludge drying and incineration offer several benefits:

· Volume Reduction: Drying significantly reduces the volume of sludge, making it easier and more cost-effective to transport and dispose of.

· Pathogen Reduction: High temperatures during incineration kill harmful pathogens present in sludge, ensuring the final disposal is safe.

· Energy Generation: Incineration converts waste into valuable heat energy, contributing to sustainable energy production.

· Resource Recovery: Incineration reduces sludge to ash, which can contain valuable minerals that can be reclaimed and reused.

· Environmental Protection: Properly managed sludge drying and incineration minimize the environmental impact of sludge disposal and prevent groundwater contamination.

In conclusion, sludge drying and incineration are vital components of modern waste management practices. These processes not only reduce the environmental impact of sludge disposal but also offer resource recovery and sustainable energy generation benefits. By implementing these solutions, we can move closer to a cleaner and more efficient waste management future. If you have any questions or want to learn more about sludge drying and incineration, please feel free to reach out to us. Together, we can make a difference in waste management practices.