BLOG

WHAT IS SLUDGE DISC DRYER?

WHAT IS SLUDGE DISC DRYER?

24 August 2023

A sludge disc dryer, also known as a sludge disk dryer or a disc dryer for sludge, is a type of industrial drying equipment used to reduce the moisture content in various types of sludge or waste materials. Sludge refers to the semi-solid byproduct generated from wastewater treatment processes, industrial processes, or other sources.

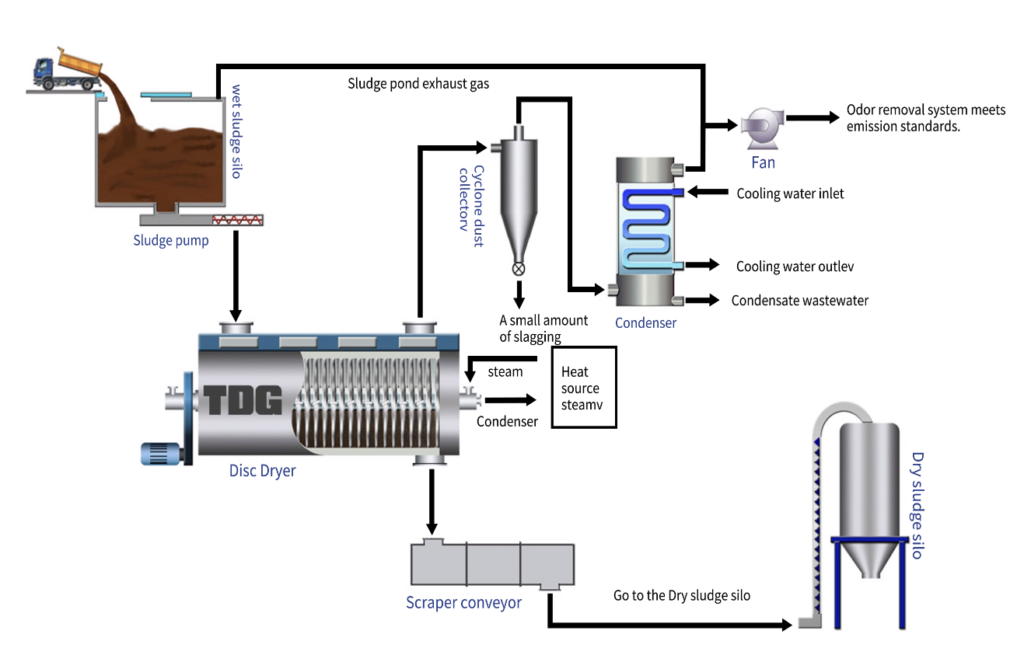

A sludge disc dryer consists of several key equipment components that work together to facilitate the drying process. The specific design and configuration of these components may vary depending on the manufacturer and the intended application.

The following are the typical equipment components you would find in a sludge disc dryer:

1. Discs: The heart of the sludge disc dryer is the rotating discs. These discs are usually arranged in a stacked formation along a central shaft or axis. They provide the surface area where the wet sludge is spread out for drying. The discs are designed with heat transfer surfaces that allow for efficient heat exchange between the heated surfaces and the sludge.

2. Central Shaft or Axis: The central shaft or axis runs through the center of the stacked discs and provides the rotation mechanism. The rotation of the shaft causes the discs to rotate, ensuring that the sludge is evenly distributed and exposed to the heated surfaces for effective drying.

3. Heating System: The heating system provides the necessary heat to facilitate the drying process. This could involve the circulation of hot air, steam, thermal oil, or other heating mediums through the heat transfer surfaces on the discs. The heat evaporates the moisture from the sludge, leaving it dry.

4. Feed System: The feed system is responsible for introducing wet sludge onto the discs. This can involve mechanisms such as feed chutes, conveyors, and distributors that evenly distribute the sludge onto the surface of the rotating discs. Uniform distribution is crucial for effective drying.

5. Scrapers or Wipers: As the sludge dries and forms a crust or cake on the disc surface, scrapers or wipers are used to continuously remove the dried sludge from the discs. This prevents excessive build-up that could hinder the drying process and ensures continuous operation.

6. Condensation System: The moisture evaporated from the sludge needs to be removed from the drying chamber. A condensation system helps to collect and remove the evaporated moisture from the drying environment. This can involve condensers, vacuum systems, or other techniques to manage the vapor.

7. Exhaust System: The exhaust system helps to remove any remaining vapor, gases, or odors from the drying process. This is important for maintaining a controlled environment and preventing any potential environmental or safety concerns.

8. Control and Monitoring System: Modern sludge disc dryers often come equipped with advanced control and monitoring systems. These systems allow operators to adjust parameters such as temperature, disc rotation speed, and other settings to optimize the drying process. They also provide feedback and alerts to ensure smooth operation.

9. Insulation and Enclosure: To maintain the efficiency of the drying process and minimize heat loss, sludge disc dryers are often equipped with insulation and enclosed in protective housing.

The sludge disc dryer operates on the principle of direct drying, where the wet sludge is spread onto the surface of a rotating disc. As the disc rotates, the sludge is exposed to heated surfaces, typically using steam or thermal oil, which causes the moisture within the sludge to evaporate. The evaporated moisture is then removed as vapor, leaving behind drier sludge with a significantly reduced moisture content.

Sludge Drying Solution of TDG TIC

The design of a sludge disc dryer typically includes multiple discs arranged on a central shaft or axis. The sludge is evenly distributed onto these discs, and the heat transfer surfaces on the discs facilitate the drying process. The rotating motion of the discs ensures that the sludge is continuously exposed to the heated surfaces, allowing for efficient drying.

Sludge disc dryers are commonly used in wastewater treatment plants, industrial facilities, and other settings where sludge management is crucial. The dried sludge produced by these dryers is often easier to handle, transport, and dispose of compared to wet or highly moist sludge. Additionally, the reduction in moisture content can also lead to a reduction in overall sludge volume, which can result in cost savings related to transportation and disposal.

Overall, the sludge disc dryer is a valuable tool in waste management and environmental sustainability efforts, as it helps to minimize the environmental impact of sludge disposal while also recovering potential energy from the dried sludge.