BLOG

What are the Applications of Disc Dryer? | Exploring a World of Industrial Efficiency and Innovation

What are the Applications of Disc Dryer? | Exploring a World of Industrial Efficiency and Innovation

06 November 2023

In the dynamic landscape of industrial processes, disc dryers have carved a niche for themselves, becoming indispensable assets in various applications. Their innovative design and advanced features cater to the diverse needs of industries, making them essential in achieving superior efficiency and high-quality outputs. This blog post will take you on a journey through the multitude of applications where disc dryers shine, showcasing their versatility and reliability across industries. Let's explore how disc dryers, with their cutting-edge technology, revolutionize industrial drying processes.

Understanding Disc Dryers:

Disc dryers are engineering marvels designed for optimal efficiency, featuring a compact design and an intricate network of welded discs that enable precise heat transfer. These machines operate on the principle of indirect heat, utilizing saturated steam at specific pressures to facilitate uniform drying. Their ability to handle various materials and maintain product integrity makes them a preferred choice in the industrial sphere.

Applications Across Industries

Animal By-Products Processing:

Disc dryers efficiently reduce the moisture content in animal by-products, transforming them into valuable materials used in the production of animal feed supplements.

Fish Meal Production:

The fish meal industry benefits from disc dryers, which lower the moisture content in fish meal, ensuring prolonged shelf life and preserving essential nutrients.

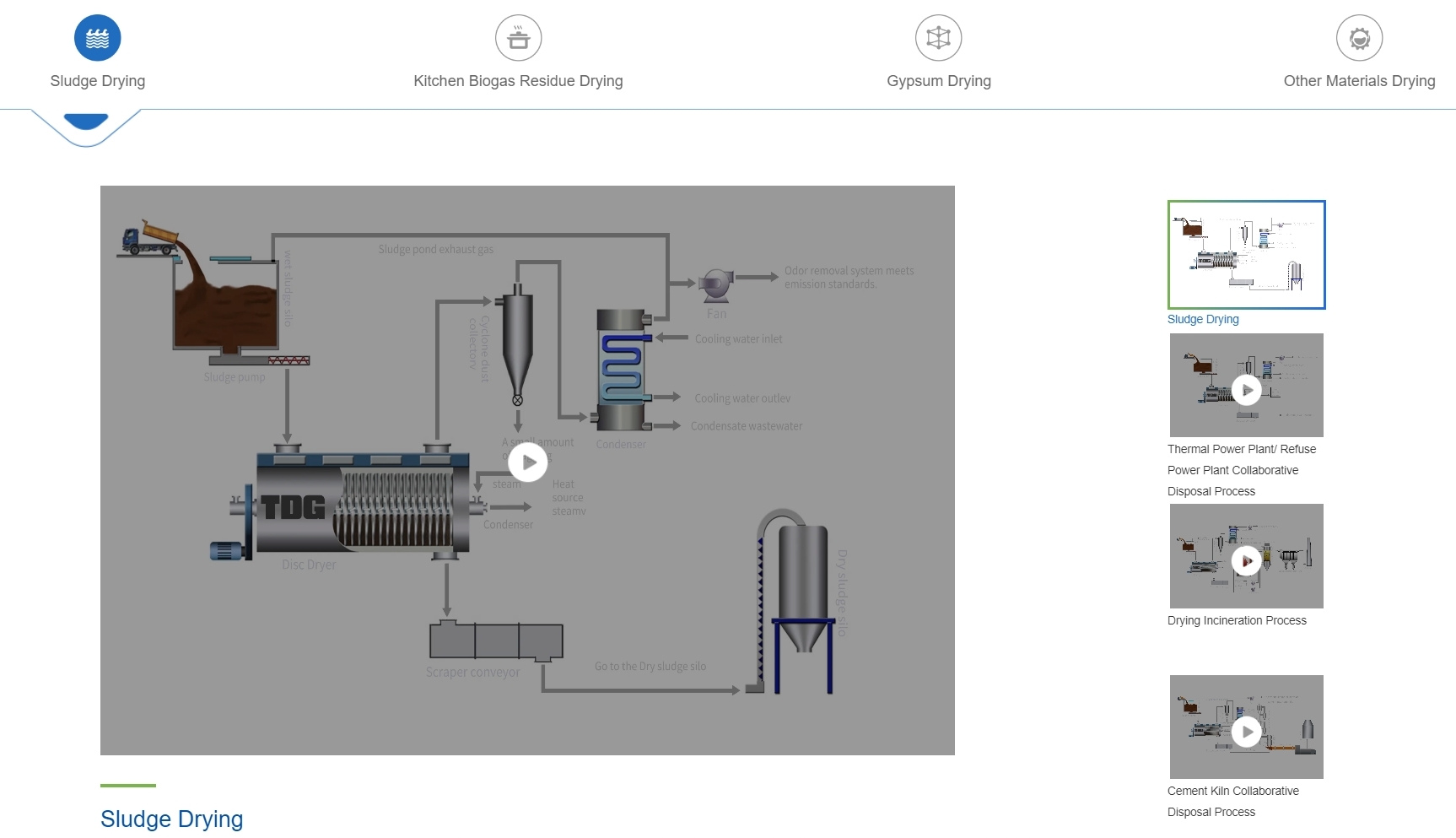

Sewage Sludge Drying:

Disc dryers play a vital role in sewage treatment solutions by drying sewage sludge, reducing volume, and enabling efficient disposal or repurposing as fertilizer.

Raw Material Drying:

Various raw materials, including agricultural products and industrial chemicals, undergo meticulous drying processes in disc dryers, ensuring consistency and high quality.

Fat Content Reduction:

Disc dryers are employed in the food industry to reduce fat content in products like oilseeds and nuts, creating healthier options without compromising taste or texture.

Space-Efficient Compact Design:

The compact design of disc dryers optimizes floor space, making them ideal for industrial facilities with limited room, maximizing production capabilities.

Optimized Heating Surface and Heat Transfer:

Disc dryers boast an optimized heating surface, ensuring efficient heat transfer and reducing energy consumption, resulting in cost-effective operations.

Precise Control with Saturated Steam and Indirect Heat:

Indirect heat transfer mechanisms, coupled with the use of saturated steam at specific pressures, allow precise control over the drying process, guaranteeing consistent and superior results.

Conclusion:

Disc dryers have emerged as pillars of industrial efficiency and innovation, addressing a wide array of applications with finesse. Their ability to optimize heat transfer, reduce moisture content, and maintain product quality underscores their significance in modern industrial processes. By embracing the cutting-edge technology of disc dryers, industries can enhance their production processes, reduce operational costs, and contribute to sustainable practices.

In a world driven by innovation and efficiency, disc dryers stand tall as symbols of industrial progress, ensuring seamless and high-quality processes in diverse sectors. Their adaptability, compact design, and precise control mechanisms make them indispensable tools, paving the way for a future of enhanced industrial productivity and sustainable practices.