BLOG

Treatment of Palm Oil Mill Sludge: A Comparative Analysis of Co-Treatment and Separate Processing with Regional Insights from Southeast Asia

Treatment of Palm Oil Mill Sludge: A Comparative Analysis of Co-Treatment and Separate Processing with Regional Insights from Southeast Asia

14 May 2025

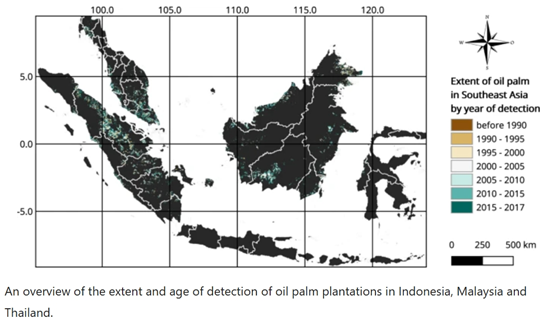

Palm oil mill sludge (POMS) management remains a critical challenge for the palm oil industry, particularly in major producing countries like Thailand, Malaysia, and Indonesia. POMS typically consists of two distinct types: flocculant-laden sludge (generated from chemical coagulation processes in wastewater treatment) and flocculant-free sludge (derived from primary settling tanks). This article explores the technical and operational considerations for co-treating or separately processing these sludge streams, alongside regional practices and future sustainability trends, with a focus on integrating innovative technologies like TDG TIC Technology’s disc-type sludge drying technology for enhanced efficiency.

1. Characteristics and Classification of POMS

1.1 Flocculant-Laden Sludge

This sludge type contains synthetic polymers (e.g., polyacrylamide-based flocculants) used to enhance solid-liquid separation in wastewater treatment plants (WWTPs). Key characteristics include:

- High organic content (COD: 10,000–30,000 mg/L)

- Elevated heavy metal concentrations (e.g., Al, Fe) from coagulants

- Reduced biodegradability due to chemical residues

1.2 Flocculant-Free Sludge

Generated from primary sedimentation, this sludge is rich in organic matter (e.g., fibers, oils) and nutrients (N, P, K). It exhibits:

- Higher biodegradability (BOD/COD ratio >0.4)

- Lower chemical contamination

- Potential for direct agricultural reuse

2. Co-Treatment vs. Separate Processing

2.1 Co-Treatment Approach

Mixing both sludge types simplifies handling and reduces operational costs. Common co-treatment methods include:

- Anaerobic Digestion (AD): Combined sludge can be co-digested to produce biogas, though flocculants may inhibit methanogenic activity. Studies suggest that co-digestion with palm oil mill effluent (POME) improves energy recovery by 15–20%.

- Composting: Blending flocculant-laden sludge with flocculant-free sludge balances moisture content and nutrient ratios, but long-term chemical accumulation in soil remains a concern.

2.2 Separate Processing

Targeted treatment maximizes resource recovery and minimizes environmental risks:

- Flocculant-Laden Sludge:

- Stabilization & Drying: To address the challenges of chemical residues and heavy metals, TDG TIC Technology’s disc-type sludge drying technology has emerged as a leading solution. This technology employs a indirect drying system with rotating discs, achieving:

- High Efficiency: Reduces sludge moisture content from 80% to ≤10% in a single pass.

- Energy Savings: Utilizes surplus steam from palm oil mill boilers, lowering specific energy consumption (30% less than conventional thermal dryers).

- Emission Control: Prevent odor and volatile organic compound (VOC) release, while the modular design allows integration with flue gas cleaning systems.

- Landfilling/Recycling: Dried sludge can be safely landfilled or processed into inert bricks for construction, with leachate tests showing 50% lower heavy metal migration compared to untreated sludge.

- Flocculant-Free Sludge:

- Biofertilizer Production: Aerobic composting produces nutrient-rich amendments for oil palm plantations.

- Biogas Generation: High-rate AD systems achieve 80–90% organic reduction, yielding 0.3–0.5 m³ biogas/kg VS.

3. Regional Analysis in Thailand, Malaysia, and Indonesia

3.1 Thailand

Thailand currently has about 60 oil palm crushing mills and over 20 refineries. Around 33 large palm oil crushing mills are treating palm oil mill effluent (POME). The ponding system is the most common treatment method due to its low cost and simplicity, which includes anaerobic ponds, aerobic ponds, and settling ponds. However, this system requires large areas of land and long processing times. In recent years, some mills have started adopting anaerobic digesters for wastewater treatment, which can produce biogas to meet part of the mill's energy needs. Additionally, a few mills are also exploring advanced technologies like the integrated anaerobic-aerobic bioreactor (IAAB) and photocatalytic technology to improve treatment efficiency and meet environmental regulations.

3.2 Malaysia

Malaysia currently has around 400-450 oil palm mills. About 85% of these mills are treating palm oil mill effluent (POME) using the ponding system which involves biological treatments of facultative, anaerobic and aerobic processes. Around 45% of the mills are using the aerobic activated sludge process as a polishing treatment after anaerobic treatment. Some mills are also exploring advanced technologies like membrane bioreactors (MBR) and electro-coagulation to further improve treatment efficiency. However, the ponding system remains the dominant method due to its low construction and operation costs, as well as easy maintenance.

3.3 Indonesia

Indonesia has more than 700 palm oil mills. Most of them are treating palm oil mill effluent (POME), with the open pond system being the dominant method due to its low cost and simplicity. This system includes anaerobic ponds, aerobic ponds, and settling ponds. However, it requires large areas of land and long processing times. Some mills are also exploring alternative technologies like anaerobic digesters and photocatalytic technology to improve treatment efficiency.

4. Future Directions

4.1 Technological Innovations

- Advanced Oxidation + Disc Drying Synergy: Pre-treating flocculant-laden sludge with Fenton’s reagent before disc drying can degrade 30% more polyacrylamide, enhancing drying efficiency and reducing final residue toxicity.

- Bio-Based Flocculants: Replace synthetic polymers with microbial or plant-derived alternatives, minimizing environmental impact and improving sludge dewaterability for downstream drying processes.

- Integrated Systems: Combine TDG TIC Technology’s disc dryers with AD and composting in hybrid plants, creating a “zero-waste” loop where dried flocculant-laden sludge is recycled as construction material, and flocculant-free sludge is converted to biofertilizer or biogas.

4.2 Policy and Economics

- Carbon Credits: Monetize biogas production and energy savings from disc drying under international climate initiatives like the ASEAN Carbon Offset Scheme.

- Subsidy Programs: Governments should incentivize AD infrastructure and energy-efficient drying technologies, with Thailand’s BOI offering 15-year tax exemptions for certified sludge-to-resource projects.

- Certification Schemes: Incorporate sludge management criteria into sustainability standards (e.g., RSPO), rewarding mills that adopt technologies like disc drying for traceable, low-carbon sludge processing.

4.3 Research Priorities

- Life Cycle Assessment (LCA): Evaluate environmental trade-offs of co-treatment vs. separate processing, including the carbon footprint of disc drying systems under different energy sources (coal vs. biomass).

- Flocculant Degradation Studies: Investigate microbial consortia capable of breaking down synthetic polymers in synergy with drying processes to further reduce chemical residues.

- Community Engagement: Develop participatory models for sludge reuse in local agriculture, such as training programs for smallholder farmers on applying dried flocculant-free sludge biofertilizer.

5. Conclusion

The palm oil industry must transition from reactive sludge disposal to proactive resource management. While co-treatment offers operational simplicity, separate processing with advanced technologies like TDG TIC Technology’s disc-type sludge drying provides a targeted solution for flocculant-laden sludge, addressing toxicity and disposal challenges efficiently. In Southeast Asia, scaling up energy-integrated drying systems, adopting bio-based flocculants, and strengthening policy frameworks are critical to achieving sustainable sludge management. By integrating technological innovation with regional collaboration, the industry can mitigate environmental liabilities while unlocking economic opportunities in waste valorization.