BLOG

The Role of TIC Technology Co., Ltd.'s Disc Dryer in Gypsum Drying

The Role of TIC Technology Co., Ltd.'s Disc Dryer in Gypsum Drying

10 July 2024

Gypsum is a widely used material in various industries, particularly in construction and manufacturing. Its drying process is a critical step in ensuring its quality and usability. TIC Technology Co., Ltd. has introduced an advanced solution for gypsum drying with their state-of-the-art disc dryer. This article explores the process of gypsum drying and the advantages offered by TIC Technology Co., Ltd.'s disc dryer.

Understanding Gypsum Drying

Gypsum, a soft sulfate mineral composed of calcium sulfate dihydrate, requires precise drying to convert it into a usable form. The drying process involves removing moisture from the raw gypsum material to produce a stable and consistent end product. Proper drying not only improves the material's strength and durability but also prevents issues such as mold growth and degradation over time.

The Disc Dryer: An Advanced Solution

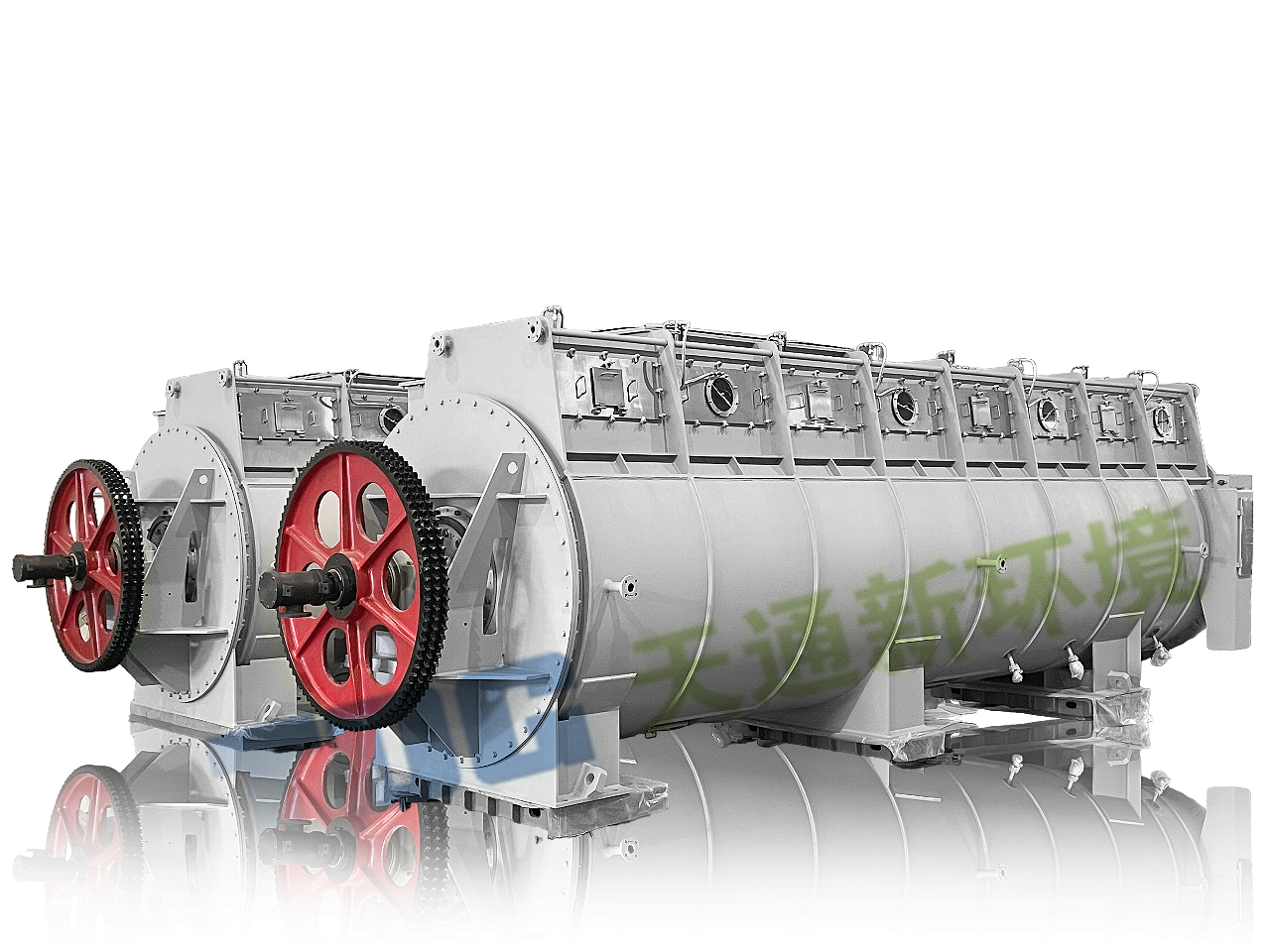

TIC Technology Co., Ltd. has developed an innovative disc dryer specifically designed for gypsum drying. This machine stands out due to its efficiency, reliability, and ability to handle large volumes of material.

Key Features of the Disc Dryer:

1、High Efficiency: The disc dryer uses a series of rotating discs to maximize the surface area for heat transfer, ensuring rapid and uniform drying. This results in higher throughput and reduced energy consumption.

2、Consistent Quality: The controlled drying environment provided by the disc dryer ensures that the gypsum is dried evenly, producing a consistent and high-quality product.

3、Durability: Built with robust materials and advanced engineering, TIC Technology Co., Ltd.'s disc dryer is designed to withstand the rigors of continuous operation, minimizing maintenance requirements and downtime.

4、Flexibility: The disc dryer can be adjusted to accommodate different types of gypsum and varying moisture levels, making it a versatile solution for different production needs.

Benefits for the Industry

The introduction of TIC Technology Co., Ltd.'s disc dryer brings several benefits to the gypsum industry:

1、Improved Productivity: With its high efficiency and capacity, the disc dryer enables manufacturers to process larger quantities of gypsum in less time, boosting overall productivity.

2、Energy Savings: The innovative design of the disc dryer reduces energy consumption, leading to cost savings and a smaller environmental footprint.

3、Enhanced Product Quality: The consistent drying process ensures that the final gypsum product meets stringent quality standards, enhancing its performance in various applications.

4、Operational Reliability: The durability and low maintenance requirements of the disc dryer contribute to more reliable and continuous operation, reducing the risk of costly interruptions.

Conclusion

The gypsum drying process is crucial for producing high-quality materials used in various industries. TIC Technology Co., Ltd.'s disc dryer offers an advanced and efficient solution for this process, providing numerous benefits in terms of productivity, energy savings, and product quality. As the industry continues to evolve, innovations like the disc dryer will play a vital role in meeting the growing demands for high-performance gypsum products.

As a sludge dryer manufacturer and disc sludge drying solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to tic@tdgtic.com.