BLOG

The Power of Sludge Dryers in Sustainable Solutions

The Power of Sludge Dryers in Sustainable Solutions

14 November 2023

In the realm of wastewater treatment, the management of sewage sludge poses a significant challenge. Traditionally, the disposal of sludge has been associated with high costs, environmental concerns, and energy inefficiencies. However, the emergence of innovative technologies, such as sludge dryers, is transforming the landscape of sludge treatment, offering sustainable and cost-effective solutions.

Sludge Treatment and Disposal Costs:

Sewage sludge, a byproduct of wastewater treatment, has long been a costly challenge for municipalities and industrial facilities. Disposal costs, coupled with environmental regulations, have driven the need for efficient and sustainable methods to handle this waste material. Traditional methods like incineration plants have drawbacks, including high energy consumption and emissions.

Energy Sources and Recovery:

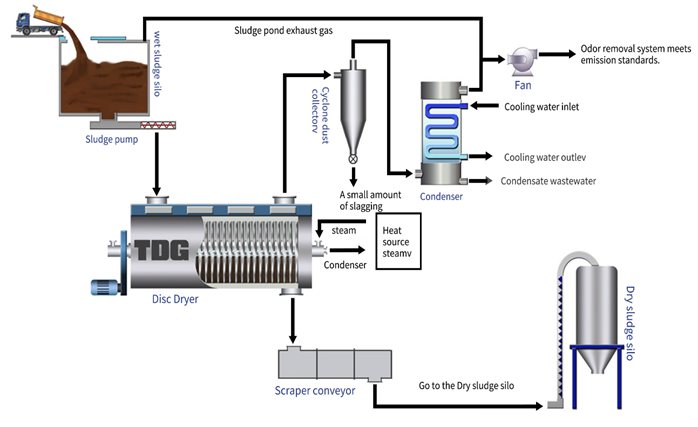

Enter the sludge dryer – a game-changer in the quest for sustainable sludge treatment. These advanced systems utilize various energy sources, with a growing emphasis on thermal energy. The integration of thermal energy not only facilitates the drying process but also opens the door to energy recovery initiatives. This not only reduces the environmental impact but also contributes to a more circular and resource-efficient approach.

System Design and Stainless Steel:

The efficiency of sludge dryers lies in their robust system design, often incorporating stainless steel components. Stainless steel is chosen for its corrosion resistance and durability, ensuring a long lifespan for the equipment. This not only reduces maintenance costs but also promotes the sustainable use of materials, aligning with the principles of a circular economy.

Drying Process and Thermal Efficiency:

The heart of the sludge dryer lies in its drying process, which efficiently removes moisture from the sludge, resulting in dry solids. Thin film technology and heat exchangers play pivotal roles in achieving high thermal efficiency, minimizing energy consumption, and maximizing the beneficial reuse of resources. The reduced volume and weight of the dried sludge further contribute to cost savings in transportation and disposal.

Beneficial Reuse of Dried Solids:

One of the most exciting aspects of sludge dryers is their ability to facilitate beneficial reuse of the dried solids. The resulting material can find applications in agriculture, construction, and other industries, turning what was once considered waste into a valuable resource. This not only reduces the environmental footprint but also supports the concept of a circular economy.

Conclusion:

In the realm of wastewater management, sludge dryers are emerging as champions of sustainability, addressing the challenges associated with sludge treatment, disposal costs, and environmental impact. The integration of thermal energy, efficient system design, and the promotion of beneficial reuse collectively contribute to a more sustainable and cost-effective approach to sludge management. As industries and municipalities continue to prioritize environmentally friendly solutions, the adoption of sludge dryers is likely to grow, paving the way for a greener and more efficient future in waste management.