BLOG

The Application of Disc Dryers in Gypsum Drying Solutions

The Application of Disc Dryers in Gypsum Drying Solutions

13 July 2023

Introduction:

In the field of gypsum drying, disc dryers have emerged as a valuable solution for companies seeking efficient and environmentally friendly processes. Disc dryers, such as the SDK and FDK series developed by TIC Technology Co., Ltd.(under TDG Holding), offer a range of specifications suitable for various industries, including gypsum, municipal waste, petrochemicals, and more. These dryers facilitate dehydration, semi-drying, and full drying of materials, while integrating system technologies for comprehensive and harmless gypsum treatment.

Advantages of Disc Dryers:

1. Versatility: Disc dryers are applicable to a wide range of materials, including gypsum, sludge, food residues, alumina hydroxide, hazardous waste sludge, coal mud, pharmaceutical residues, and fertilizers.

2. Steam as the Heat Transfer Medium: These dryers utilize steam for heat transfer, enabling both semi-drying and full drying processes. This approach simplifies the system and reduces the need for auxiliary equipment.

3. Efficient Exhaust System: Disc dryers feature a gas supply port that ensures smooth exhaust emissions, requiring minimal auxiliary air and reducing the size of exhaust treatment equipment.

4. Enhanced Safety: During operation, disc dryers maintain low oxygen levels, temperature, and dust concentration, ensuring a high level of system safety.

5. Compact Design: With heat transfer occurring through the shell, hollow shaft, and both sides of each vertical disc, disc dryers offer a large heat transfer area in a compact structure with small dimensions.

6. Agitation and Cleaning Mechanism: To prevent gypsum from adhering to the discs, fixed long scrapers are installed on the inner wall of the shell, effectively stirring and cleaning the disc surfaces. This results in uniformly granulated gypsum, facilitating further processing.

7. Stable Operation: Disc dryers can handle significant processing loads, ensuring smooth operation even with uneven feed distribution. The internal resistance is minimal, resulting in significantly reduced power consumption.

8. Ease of Maintenance: The upper cover of the dryer can be fully opened, facilitating maintenance operations.

9. High Reliability: Disc dryers require minimal repairs, offer excellent continuous operation performance, and can run 8,000 hours per year, ensuring a long operational lifespan.

10. Sturdy Construction: Built with durable stainless steel materials, disc dryers are designed for long-term and reliable operation.

Gypsum Drying Solution:

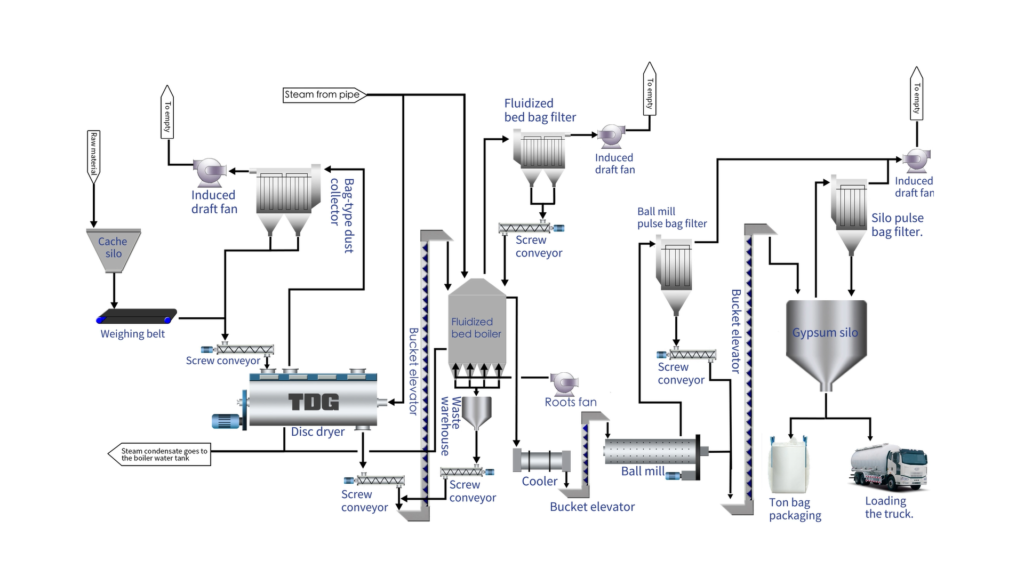

After desulfurized gypsum is transported to the cache silo, it is screened and weighed by belt. Then the material is evenly sent to the disc dryer for drying. And then screw conveyor and bucket elevator input into the furnace for calcining into Building gypsum. The building gypsum from the furnace is transported to the ball mil through the conveying equipment. The metal ball in the ball mill constantly impinges with the building gypsum to realize the pulverized of the building gypsum, and then sent to the gypsum silo for storage. There are bulk machine and ton charter at the bottom of the silo, which can realize bulk and ton packing and small bag packing.

Working Principle of Disc Dryers:

Materials are fed into the dryer through the inlet and transferred between the shell and hollow shaft. Heat transfer occurs through the jacket, hollow shaft, and welded hollow discs mounted on the shaft. Indirect heating causes moisture to evaporate, and the resulting steam collects in the dome of the dryer, being carried out by the carrier gas. The hollow discs are arranged almost perpendicular to the shaft and agitate the materials, constantly refreshing the drying surface and achieving the desired drying effect.

Conclusion:

The application of disc dryers in gypsum drying processes offers numerous benefits for industries aiming to achieve sustainable and efficient operations. With their versatile capabilities, compact design, and low energy consumption, disc dryers have become an indispensable solution for companies focusing on gypsum recycling and harmless treatment. The reliable performance and long lifespan of disc dryers contribute to the realization of a beautiful and sustainable environment in China.