BLOG

The Advantages of Disc Dryers for Effective Sludge Drying and Disposal

The Advantages of Disc Dryers for Effective Sludge Drying and Disposal

03 July 2023

Introduction:

In today's world, efficient and eco-friendly solutions for waste management are crucial. TIC Technology (under TDG Holding), a leading company in this field, offers a cutting-edge solution for sludge drying and disposal: the disc dryer. This blog post aims to provide a clear and concise overview of disc dryers, their benefits, and their role in promoting sustainable waste management practices. Whether you're a student or a professional, this article will help you understand the significance of disc dryers in the realm of waste treatment.

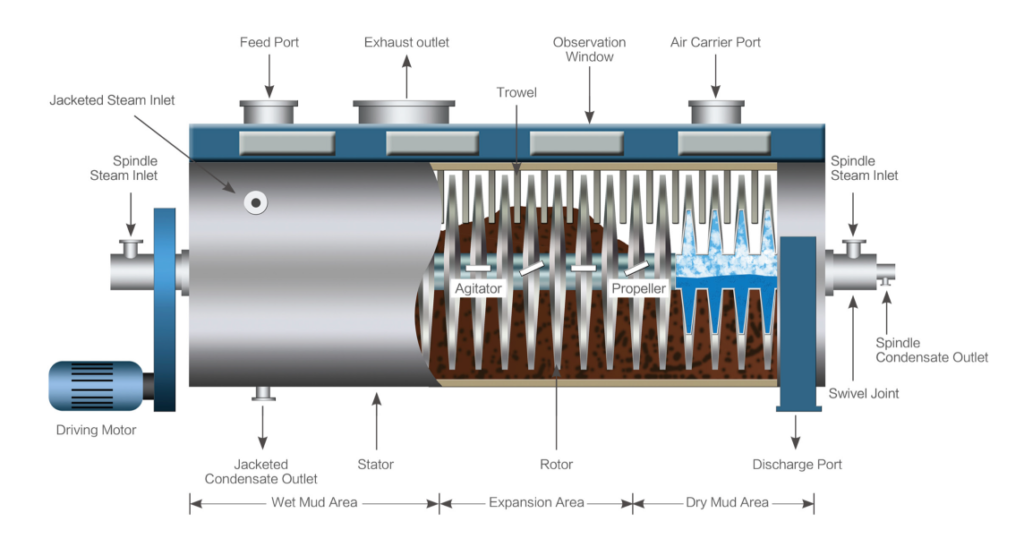

Disc Dryer: An Innovative Approach to Sludge Drying Sludge, a byproduct of various industrial processes and wastewater treatment plants, requires proper disposal to prevent environmental contamination. The disc dryer system provides an efficient and reliable method for sludge drying, ensuring the safe and complete treatment of sludge. This technology can be seamlessly integrated with power plants, sewage treatment facilities, and waste incineration plants to achieve optimal sludge management.

How does the Disc Dryer System Work?

1. Sludge Collection:

Wet sludge is transported to a storage facility through specialized vehicles. The storage facility, equipped with an automatic cover, prevents the spread of odors.

2. Sludge Drying:

The truck-mounted sludge is fed into the wet sludge silo, then transported to the disk dryer through a wet sludge conveying device. The steam is used as a heating source, and the heat is transmitted through the jacket, the hollow shaft, and the hollow plate. The sludge is heated and dried indirectly. Inside the disc dryer, the sludge is heated and evaporated while slowly moving forward. This process generates a significant amount of tail gas.

3. Tail Gas Treatment:

To remove the tail gas from the disc dryer, external air is introduced, creating an airflow that carries the gas to the subsequent treatment system. The dried sludge, meeting the desired requirements, exits the dryer and is transported to a storage facility or incineration system using a scraper conveyor.

4. Post-Treatment and Emission Control:

The exhaust gas, carrying traces of water vapor, enters a cyclone dust collector for purification. After the dust collector removes particulate matter, the gas passes through a condenser. Some of the gas condenses into wastewater, while the remaining non-condensable gases can either be incinerated in a boiler or undergo further treatment in deodorization system. The treated gas is then discharged through a high-altitude emission system, complying with emission standards.

Advantages of Disc Dryers:

1. Adaptable and Reliable:

The disc dryer system can handle various materials, including sludge, food residue, pharmaceutical waste, alcohol residue, fertilizers, and resins, making it highly adaptable to different drying requirements.

2. Efficient Drying Process:

By utilizing steam as the heat transfer medium, the system can operate in both semi-drying and full-drying modes. The process is straightforward, requiring minimal auxiliary equipment and ensuring a smooth discharge of exhaust gases.

3. Environmental Friendliness:

Since the sludge does not come into direct contact with steam, the exhaust gas contains a minimal amount of insoluble gases, making it suitable for incineration without causing secondary pollution. The system also features a negative pressure system, preventing any unfavorable effects from the release of odorous gases into the surrounding environment.

4. Compact and Safe Design:

The disc dryer's horizontal configuration and extensive heat transfer area enable efficient drying while maintaining a small footprint. The system operates with low oxygen levels, low temperatures, and low dust concentrations, ensuring a safe working environment.

5. Robust and Energy-Efficient:

The disc dryer's construction is durable, requiring minimal maintenance and enabling continuous operation for up to 8,000 hours annually. It can handle uneven feeding and runs on low power, resulting in significantly reduced energy consumption.

Conclusion:

Disc dryers offer an innovative and sustainable solution for sludge drying and disposal, aligning with the growing demand for waste reduction, harmlessness, stabilization, and resource utilization. TDG TIC Technology's state-of-the-art disc dryer systems provide numerous advantages, including efficient drying, minimal environmental impact, and reliable operation. By implementing these advanced technologies, we can achieve efficient waste management practices while preserving our environment for future generations.

Note: This blog post provides a brief overview of disc dryers and their benefits. For more detailed information or inquiries, readers are encouraged to visit the official website of TDG TIC Technology ( https://en.tdgtic.com ) or consult us directly. ( Tel: +86-573-83381840 E-mail: tic@tdgtic.com)