BLOG

TDG TIC’s Super Disc Dryer, to solve your sludge challenges

TDG TIC’s Super Disc Dryer, to solve your sludge challenges

04 December 2023

TIC Technology Co., Ltd. specializes in the comprehensive lifecycle management of waste treatment facilities, covering development, design, production, installation, and after-sales service. Our focus extends to the treatment and disposal of various waste types, including municipal refuse and sewage sludge.

1. Overview

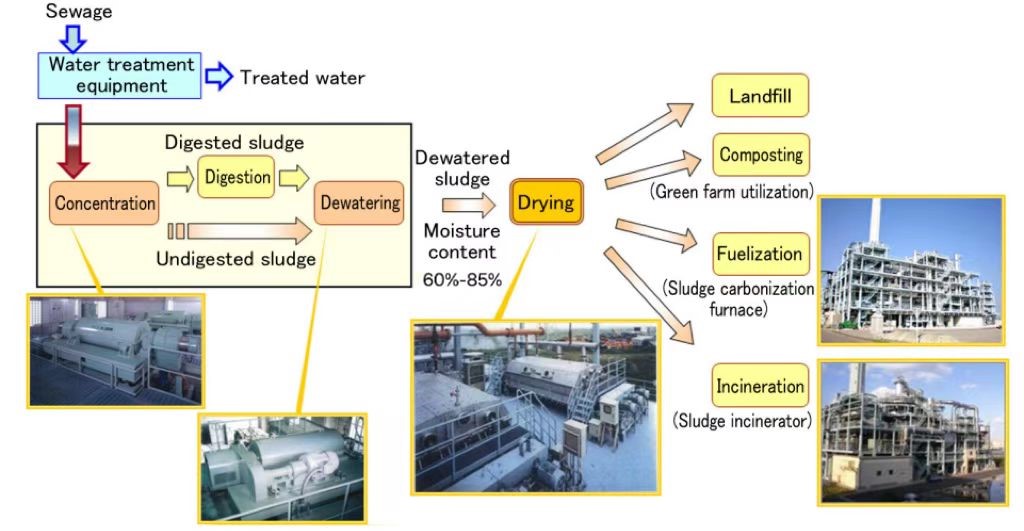

The growing volume of sludge discharge, both nationally and internationally, driven by the complexities of socioeconomic activities and stricter landfill regulations, has necessitated innovative solutions. Responding to the evolving characteristics of sludge, we have fully introduced Mitsubishi technology for an advanced sludge dryer capable of efficiently drying even challenging high-viscosity sludge. This breakthrough technology facilitates volume reduction, allowing for the sustainable recycling of sludge and contributing to the reduction of sanitary landfill reliance.

Sludge treatment technology of TIC Technology

2. Basic structure & technological features of TDG TIC’s disc dryer

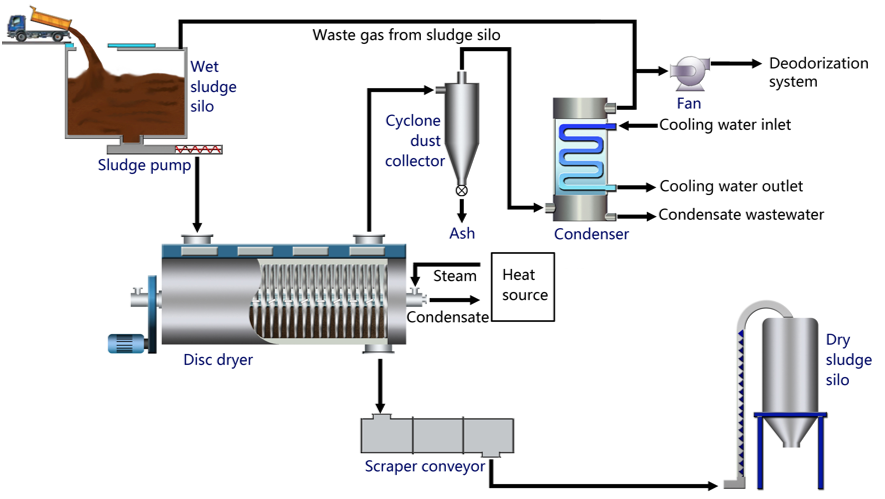

The structure and technological features of this dryer are described below.

Sludge dryer system flow

2.1 Disk-type indirectly steam-heated dryer

(1) Adoption of an Indirectly Heated Type

While directly heated dryers (air heating, flush, and belt dryers) offer stable operation and high-capacity treatment for various sludge types, they often produce significant odorous emissions, requiring extensive deodorizing equipment. Moreover, they tend to consume more fuel due to higher heat source temperatures. In contrast, indirectly heated dryers, such as the TIC's steam-based system, are thermally efficient. They exchange heat indirectly, resulting in fewer odorous gas emissions, reducing operational costs, and simplifying deodorizing equipment.

(2) Unique Single Disk-Type Dryer Structure

The single disk design excels in carrying high-viscosity sludge, effectively scraping off adhered sludge, minimizing adhesion and clogging. This structure ensures stable operation even with diverse sludge characteristics compared to other indirectly heated dryers.

(3) Steam Utilization as Drying Heat Source

Effective use of surplus steam from the factory or neighboring facilities, such as sludge or refuse incinerators and power plants, further reduces running costs.

2.2 Stable Operation and Drying Performance

The optimized disk shape and basic structure result from fundamental research, enhancing stirring and mixing efficiency. This allows thorough stirring and mixing of sludge on the disk's heat transfer surface, ensuring stable operation with a variety of high-viscosity sludge. The evaluation of transport performance and drying characteristics optimizes operational conditions, ensuring stability.

2.3 Reduction of Life Cycle Costs through Sludge Volume Reduction

The sludge dryer substantially reduces the disposal volume, making it more cost-effective than landfill disposal. This translates to reduced life cycle costs for sludge management.

3. The Benefits of TIC's Disc Dryer

3.1 Compact Design

The TDG TIC disc dryer boasts a compact design, making it suitable for installation in limited spaces or integration into existing plants.

3.2 Recyclable and Sustainable System

The system allows the recovery of energy by precipitating water evaporated from sewage sludge in the vapor condenser during thermal drying.

3.3 Internationally Recognized Technology

Adopted from Mitsubishi, TIC Technology Co., Ltd. fully owns the technology. We offer reliable, tailored sludge drying solutions treatment.

3.4 Proven and Durable Technology

With over 15 years of successful use and 200+ projects, the disc dryers in sewage sludge incineration plants demonstrate the robustness of the technology.

3.5 Stable Operation

Designed for fully automatic 24/7 operation, the TDG TIC disc dryer operates for 8,000 hours annually.

3.6 Long Service Life

The special welded construction extends the service life, reducing the minimum permissible residual wall thickness and ensuring durability for up to 20 years.

A disc dryer is lifted into place

with the help of a heavy-duty crane

Disc dryer being placed in the building

As a sludge dryer manufacturer and disc sludge drying solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to tic@tdgtic.com.