BLOG

Sludge Drying Technology: Highlighting the Rotary Disc Drying and Mitsubishi's Advanced Solution

Sludge Drying Technology: Highlighting the Rotary Disc Drying and Mitsubishi's Advanced Solution

16 July 2024

In the realm of environmental engineering and waste management, sludge drying technology plays a pivotal role in transforming waste into manageable and potentially reusable materials. Among the various drying methods, rotary disc drying, particularly the advanced technology offered by Mitsubishi, has emerged as a leading solution for sludge treatment. TIC Technology Co., Ltd., recognizing the significance of this technology, has successfully integrated Mitsubishi's rotary disc drying systems, propelling the company to the forefront of the sludge drying industry.

Introduction to Sludge Drying

Sludge drying, also known as sludge dehydration, is the process of removing a significant portion of water from sludge through filtration, evaporation, or a combination of both. This process is crucial for reducing the volume and weight of sludge, making it easier to transport, store, and ultimately dispose of or reuse. Two primary methods are employed in sludge drying: natural evaporation (sludge drying) and mechanical dehydration (sludge dewatering).

Rotary Disc Drying: A Comprehensive Overview

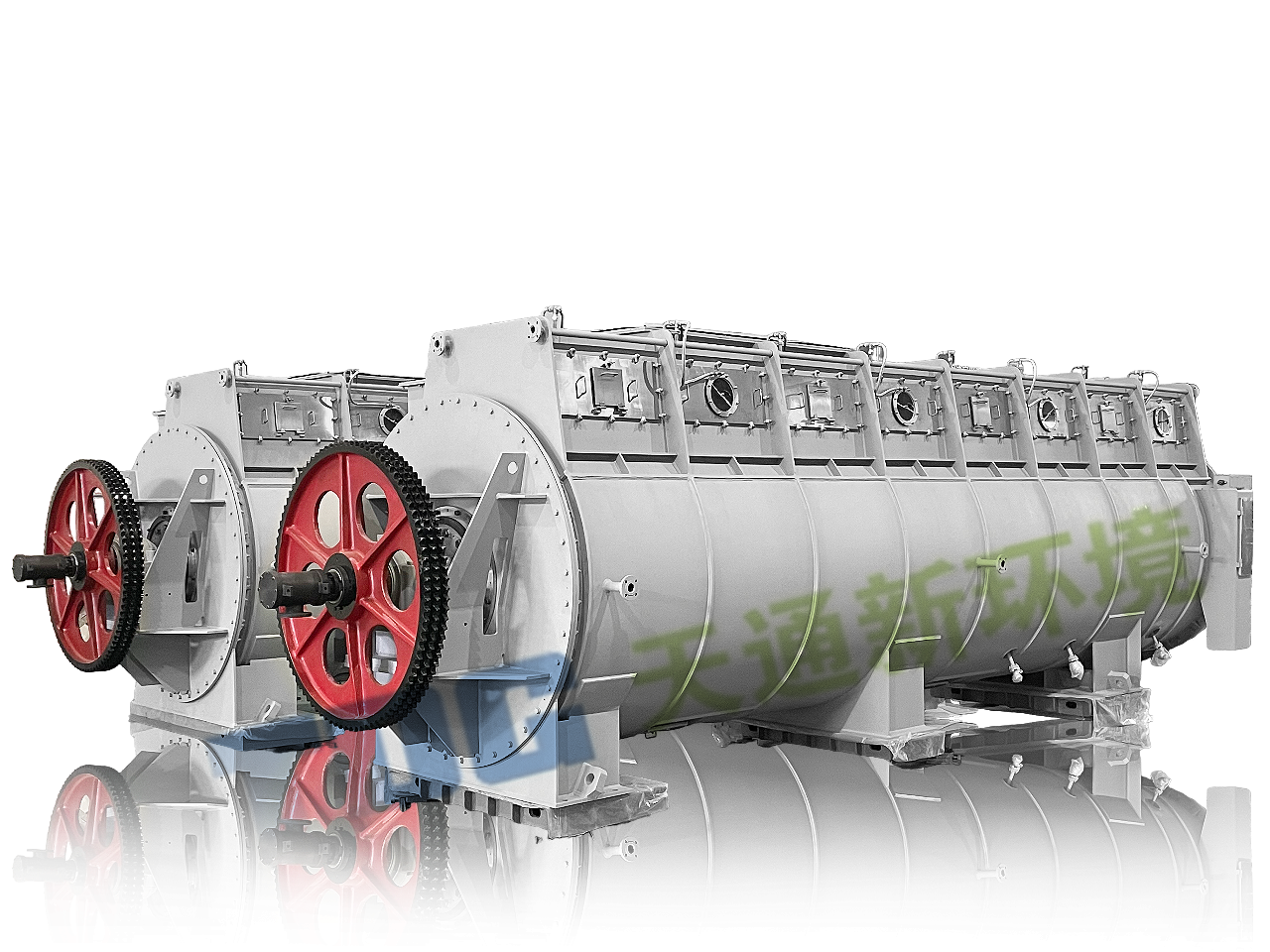

Rotary disc drying is a highly efficient mechanical dehydration method that leverages the principles of heat transfer and mechanical agitation. This technology utilizes a series of rotating discs arranged within a cylindrical housing. As the discs rotate, sludge is fed into the system and subjected to both centrifugal force and heat, facilitating rapid water evaporation.

Key Components of a Rotary Disc Dryer

Rotating Discs: The heart of the system, the rotating discs are hollow and designed to transfer heat efficiently to the sludge.

Feed Mechanism: Ensures continuous and even distribution of sludge onto the rotating discs.

Heating System: Typically uses steam, hot oil, or hot water to heat the discs, transferring heat to the sludge.

Scraper Blades: Located between discs, these blades prevent sludge build-up and ensure even drying.

Exhaust System: Collects and vents evaporated water vapor from the system.

Mitsubishi's Rotary Disc Drying Technology

Mitsubishi's rotary disc drying technology stands out for its reliability, energy efficiency, and versatility. The company's design integrates cutting-edge materials, precise control systems, and optimized process flows, making it an ideal choice for TIC Technology Co., Ltd.

High Durability: Mitsubishi's discs and associated components are made from durable materials capable of withstanding the rigors of continuous operation.

Efficient Heat Transfer: The hollow discs are optimized for maximum heat transfer, reducing energy consumption and drying time.

Adaptability: The system can be tailored to handle various types of sludge, including those with high viscosity and sand content.

Easy Maintenance: Designed for easy access and maintenance, Mitsubishi's rotary disc dryers minimize downtime and operational costs.

TIC Technology Co., Ltd.'s Leadership in Sludge Drying

TIC Technology Co., Ltd., by adopting Mitsubishi's rotary disc drying technology, has solidified its position as a leader in the sludge drying industry. The company's expertise in integrating and optimizing these systems has enabled it to provide tailored solutions for a wide range of clients, from municipal wastewater treatment plants to industrial facilities.TIC Technology Co., Ltd.'s rotary disc drying systems have proven to be highly effective in reducing sludge volume, improving handling characteristics, and reducing the environmental footprint of sludge disposal. With the help of Mitsubishi's technology, TIC Technology Co., Ltd. continues to drive innovation and sustainability in the sludge management sector.

Conclusion

In conclusion, rotary disc drying technology, particularly when powered by Mitsubishi's advanced solutions, represents a significant step forward in sludge management. TIC Technology Co., Ltd.'s commitment to integrating and optimizing this technology underscores its dedication to providing efficient, reliable, and sustainable sludge drying solutions. As the demand for waste management solutions grows, TIC Technology Co., Ltd. will continue to play a crucial role in advancing the industry and promoting a cleaner, more sustainable future.

As a sludge dryer manufacturer and disc sludge drying solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to tic@tdgtic.com.