BLOG

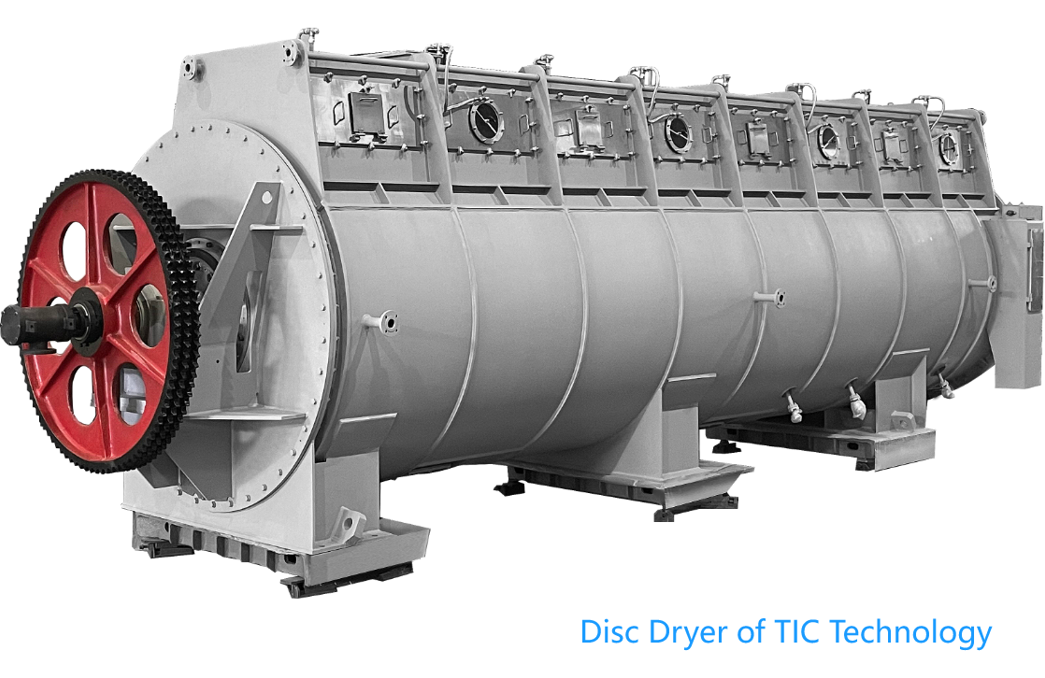

Maximizing Efficiency and Quality: Unveiling the Wonders of Disc Dryers

Maximizing Efficiency and Quality: Unveiling the Wonders of Disc Dryers

07 October 2023

In the ever-evolving landscape of industrial processes, the quest for efficiency and quality remains a paramount concern. When it comes to drying various materials, the disc dryer stands out as a technological marvel, employing a sophisticated interplay of mechanics and thermodynamics. In this blog, we will delve into the intricate world of disc dryers, exploring their functionality, applications, and the myriad ways they optimize processes while ensuring high-quality outcomes.

Understanding the Basics:

At the heart of disc dryers lies the principle of heat transfer, wherein raw materials undergo a meticulous drying process. The efficiency of this drying method is influenced by several critical factors, including fat content, floor space, heating surface, steam pressures, and surface area. Manufacturers must consider these elements to design a disc dryer that caters to specific material requirements.

Innovative Design and Functionality:

Disc dryers boast a compact design, optimizing floor space utilization without compromising efficiency. The drying process involves indirect heat, where saturated steam is utilized to evaporate water from the material. The intricate system of discs, featuring welded surfaces, ensures an extended heat transfer surface. This design allows for precise steam control, enabling manufacturers to maintain optimal drying conditions.

Versatile Applications:

Disc dryers find application across a diverse range of industries. From processing animal by-products to drying sewage sludge and fish meal, these dryers have proven indispensable. Their ability to handle various materials, including dried material and dry products, highlights their versatility. Moreover, the controlled drying process ensures that the integrity of the material is maintained, making them particularly suitable for sensitive applications.

Enhancing Sustainability:

In the realm of environmental consciousness, disc dryers play a crucial role. By utilizing water vapor and indirect heat, they minimize energy consumption while maximizing efficiency. Furthermore, their capacity to process sewage sludge and other organic materials aligns with sustainable practices, contributing to waste reduction and resource optimization.

The Future of Drying Processes:

As technology continues to advance, the future of disc dryers looks promising. Ongoing research and development efforts focus on refining heat transfer mechanisms, exploring innovative materials, and improving steam control systems. These advancements aim to enhance the overall efficiency of disc dryers, making them even more indispensable in various industrial sectors.

In conclusion, disc dryers epitomize the fusion of engineering brilliance and environmental responsibility. Their ability to handle diverse materials, coupled with their energy-efficient design, makes them indispensable in modern industrial processes. As industries strive for greater efficiency and sustainability, the disc dryer stands tall as a beacon of innovation, offering a glimpse into the future of drying technologies.