BLOG

Industrial Sludge Treatment: Advancing Sustainability with Mitsubishi Disc Dryers by TIC Technology Co., Ltd.

Industrial Sludge Treatment: Advancing Sustainability with Mitsubishi Disc Dryers by TIC Technology Co., Ltd.

26 July 2024

The Burden of Industrial Sludge

Industrial sludge, a heterogeneous mixture of solids, liquids, and gases, poses significant challenges to both the environment and the economy. Its high moisture content makes transportation and disposal costly and inefficient, while the presence of hazardous substances threatens soil, water, and air quality. Traditional methods of sludge treatment, such as landfilling or incineration, are often insufficient in addressing these concerns, necessitating the development of more advanced and sustainable solutions.

TIC Fully Introduced Mitsubishi's Disc Dryers

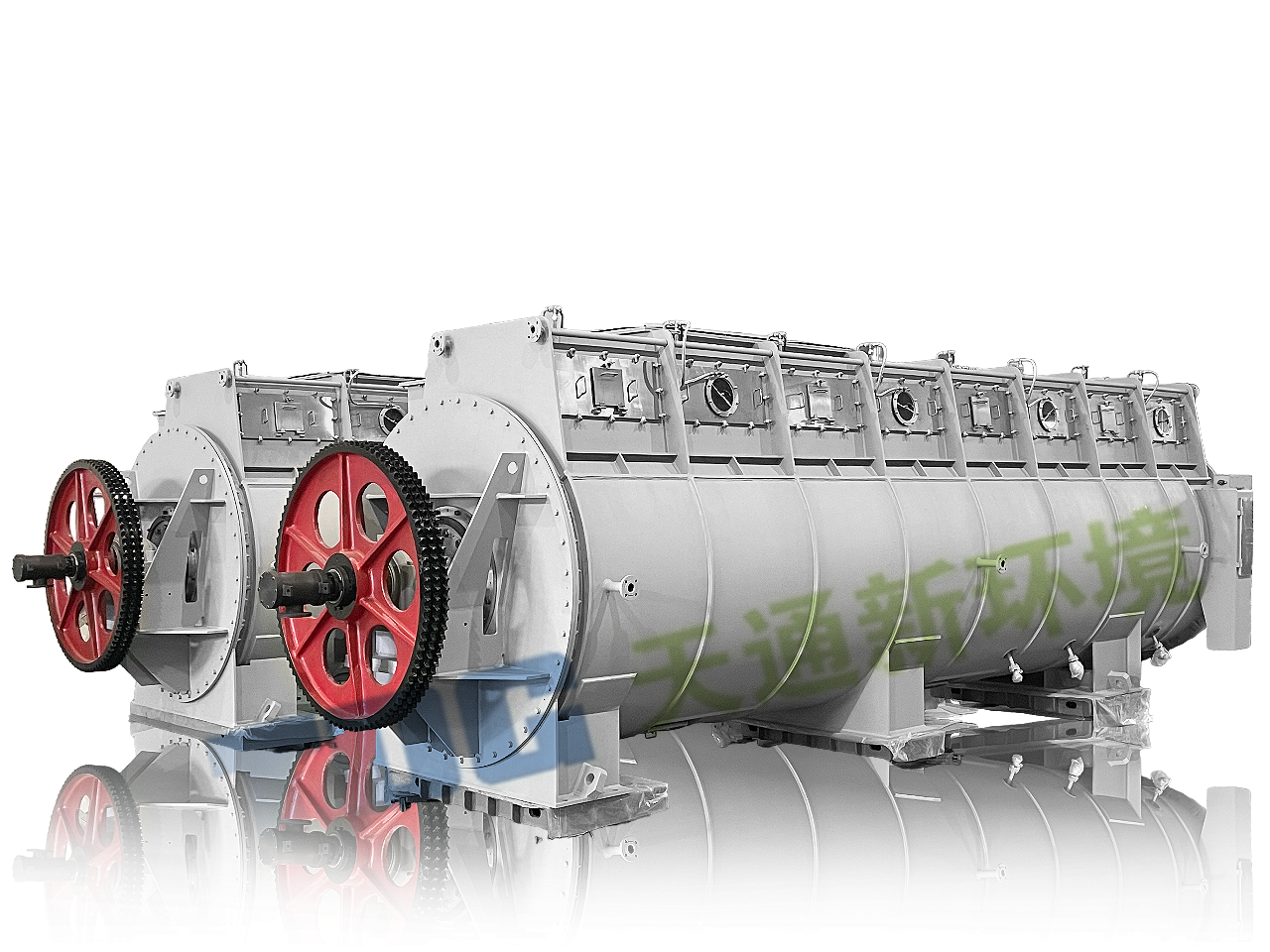

TIC Technology Co., Ltd., recognizing the urgency of this issue, has embraced Mitsubishi's cutting-edge disc dryer technology as a game-changer in industrial sludge treatment. These dryers represent a revolution in sludge management, offering unparalleled efficiency, reliability, and environmental friendliness.

The Mitsubishi disc dryers operate on a principle of indirect heat transfer, utilizing a series of rotating discs to evenly distribute and heat the sludge. As the sludge passes through the heated discs, the moisture is gradually evaporated, resulting in a significant reduction in sludge volume and weight. This process not only facilitates easier transportation and disposal but also enhances the sludge's suitability for further treatment or even resource recovery.

One of the key advantages of Mitsubishi's disc dryers lies in their precise temperature control capabilities. By maintaining optimal drying temperatures, the technology minimizes the risk of harmful emissions and ensures that the sludge's organic matter is preserved, enhancing its potential for reuse or conversion into valuable byproducts. Additionally, the energy efficiency of these dryers is remarkable, utilizing low-grade heat sources such as steam or hot water, reducing operational costs and carbon footprint.

TIC Technology's Leadership Role

TIC Technology Co., Ltd.'s decision to incorporate Mitsubishi's disc dryers into its sludge treatment portfolio underscores the company's commitment to driving sustainability and innovation in the industrial sector. By providing clients with access to this advanced technology, TIC Technology is enabling them to overcome the challenges associated with sludge management, fostering a more environmentally responsible and economically viable approach to production.

The widespread adoption of Mitsubishi's disc dryers by TIC Technology's clientele has led to numerous success stories across various industries. From chemical plants to food processing facilities, these machines have proven their mettle in handling a diverse range of sludge types and compositions. Their versatility and reliability have earned them a reputation as the go-to solution for industrial sludge treatment, setting new standards for efficiency, safety, and sustainability.

Conclusion

In conclusion, the partnership between TIC Technology Co., Ltd. and Mitsubishi in the field of industrial sludge treatment represents a significant step forward in addressing the environmental and economic challenges associated with this issue. By harnessing the power of Mitsubishi's innovative disc dryer technology, TIC Technology is enabling industries to adopt more sustainable and efficient practices, ultimately contributing to a cleaner, healthier planet. As the demand for environmentally responsible solutions continues to grow, the impact of this partnership is poised to be felt for years to come, shaping the future of sludge management and fostering a more sustainable industrial landscape.

As a sludge dryer manufacturer and disc sludge drying solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to tic@tdgtic.com.