BLOG

How does a sludge screw press work?

How does a sludge screw press work?

15 August 2023

Introduction:

In the realm of wastewater treatment, innovative technologies have paved the way for more efficient and environmentally-friendly solutions. One such technology is the sludge screw press, a powerful tool used to dewater sludge. In this blog, we'll delve into the workings of a sludge screw press, offering a clear and straightforward explanation of its operation.

Understanding the Sludge Screw Press:

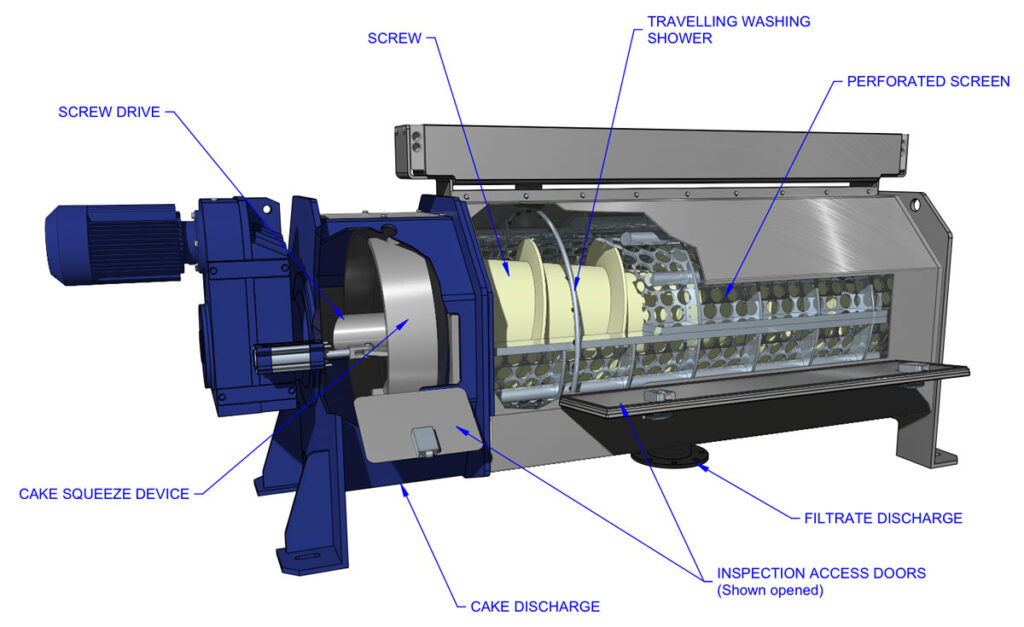

A sludge screw press, also known as a sludge dewatering screw press, is a mechanical device designed to separate water from sludge generated during wastewater treatment processes. It achieves this by utilizing a combination of mechanical pressure and gradual dewatering.

The Operation Process:

1. Sludge Infeed:

The process begins with the introduction of sludge into the press. This sludge is typically a semi-solid mixture of water and solids obtained from sewage treatment or industrial processes.

2. Conditioning:

Before dewatering begins, chemicals or polymers are often added to the sludge. These additives aid in the flocculation of the fine solids, making them more conducive to separation.

3. Conditioning:

The heart of the sludge screw press is a continuously rotating screw conveyor. This conveyor consists of a helical screw surrounded by a cylindrical screen. As the screw rotates, it gradually pushes the sludge towards the outlet end.

4. Dewatering and Compression:

As the sludge moves along the screw conveyor, the combination of the screw's rotation and the gradually narrowing cylindrical screen creates mechanical pressure. This pressure squeezes the sludge, forcing water to pass through the screen's openings.

5. Water Separation:

The water content within the sludge is separated from the solids due to the mechanical pressure. The separated water passes through the screen and is collected for further treatment or disposal.

6. Cake Discharge:

The dewatered sludge, now resembling a cake-like consistency, continues to be pushed by the screw conveyor until it reaches the discharge end. At this point, it's expelled from the press and can be further processed, incinerated, or disposed of in an environmentally responsible manner.

Conclusion:

The sludge screw press presents a practical solution for efficiently reducing the water content in sludge generated by wastewater treatment. Through a straightforward mechanical process, it effectively separates water from sludge, resulting in a drier and more manageable waste product. This innovative technology not only contributes to effective wastewater management but also showcases the continuous advancements in sustainable practices within the field of environmental engineering.