BLOG

Exploring the Versatility of Sludge Dryers

Exploring the Versatility of Sludge Dryers

28 November 2023

In the dynamic landscape of industrial waste management, sludge dryers have emerged as vital tools in the quest for sustainable solutions. As industrial dryer manufacturers continually innovate, a variety of cutting-edge dryers, such as rotary dryers, torus disc dryers, rapid disc dryers, and vacuum disc dryers, have become instrumental in the efficient drying of civil and industrial sludge. In this blog post, we'll explore the role of these diverse sludge dryers and the impact they have on industrial drying practices.

- The Evolution of Sludge Drying:

Industrial drying equipment has come a long way in addressing the challenges posed by sludge drying. Today, various types of sludge dryers, ranging from traditional rotary drum dryers to advanced torus and disc dryers, offer tailored solutions to meet the diverse needs of different industries.

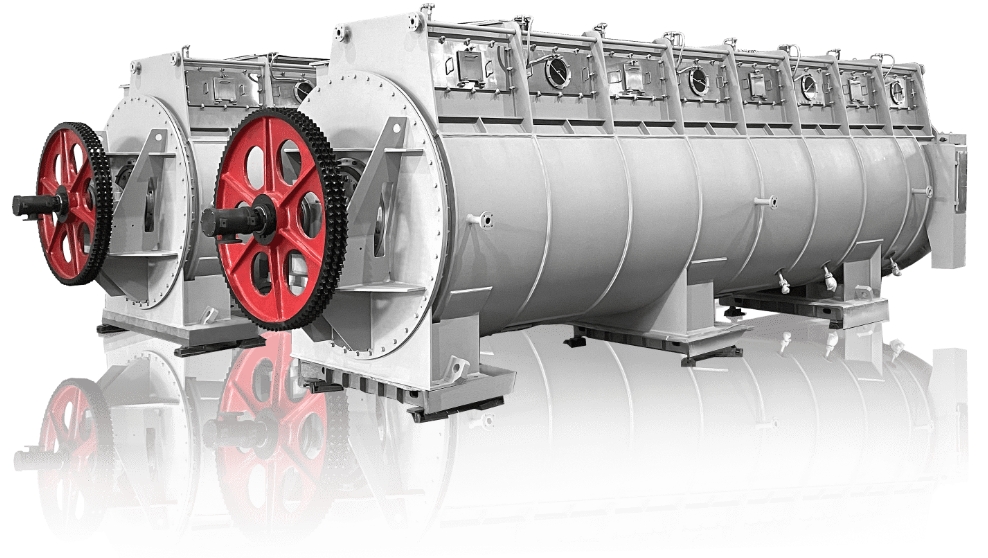

- Rotary Dryers: The Time-Tested Workhorses

Rotary dryers have been the stalwarts in sludge drying for years. These industrial drying giants efficiently remove moisture from sludge, making it suitable for disposal or further processing. With a simple and robust design, rotary dryers continue to play a key role in sludge drying applications.

- Torus Disc Dryers: Precision in Drying

Torus disc dryers represent a leap forward in sludge drying technology. Their innovative design maximizes the heat transfer surface area, ensuring rapid and efficient drying. These compact and efficient dryers are particularly well-suited for industrial applications where space is a premium.

- Rapid Disc Dryers: Speed and Efficiency Combined

As the name suggests, rapid disc dryers prioritize speed without compromising efficiency. These dryers excel in quickly reducing sludge moisture content, making them valuable assets for industries with high throughput requirements. The rapid disc dryer's design allows for swift and precise drying processes.

- Vacuum Disc Dryers: Pioneering Environmental Sustainability

Vacuum disc dryers bring an eco-friendly dimension to sludge drying. By operating under vacuum conditions, these dryers minimize energy consumption while maximizing efficiency. This not only contributes to cost savings but also aligns with the growing emphasis on sustainable industrial practices.

- The Role of Industrial Dryer Manufacturers:

The evolution of sludge dryers would not be possible without the ingenuity of industrial dryer manufacturers. These entities play a crucial role in developing and refining drying equipment, pushing the boundaries of what is possible in the realm of sludge drying. Their continuous innovation ensures that the latest technologies are available to industries seeking efficient and sustainable sludge drying solutions.

SLUDGE DRYER MANUFACTURER ( TDG TIC TECHNOLOGY )

Conclusion:

In conclusion, the diverse array of sludge dryers, including rotary dryers, torus disc dryers, rapid disc dryers, and vacuum disc dryers, represents a significant leap forward in industrial waste management. As industrial dryer manufacturers continue to push the envelope of innovation, sludge dryers stand as beacons of efficiency, offering versatile and sustainable solutions for the drying of civil and industrial sludge. In a world increasingly focused on environmental responsibility, these advancements in sludge drying technology mark a significant step toward a more sustainable and efficient future in waste management.