BLOG

Evolution of Sludge Disc Dryers: A Milestone in Waste Management

Evolution of Sludge Disc Dryers: A Milestone in Waste Management

08 August 2024

Evolution of Sludge Disc Dryers: A Milestone in Waste Management

In the realm of waste management, sludge treatment has emerged as a critical process for addressing the challenges posed by industrial and municipal wastewater treatment. Among the various technologies employed, the sludge disc dryer has undergone a remarkable evolution, transforming from a niche equipment to a ubiquitous solution in modern waste management practices. This article delves into the fascinating journey of sludge disc dryers, tracing their origins, advancements, and current applications.

Origins: Pioneering Innovation

The story of sludge disc dryers dates back to the 1940s, when Mr. Batz of Norway pioneered the development of rotary disc dryers and secured a patent for his invention. Initially designed for drying fish powder, this innovative machinery soon found broader applications, marking the beginning of a revolution in sludge treatment. The early disc dryers demonstrated their potential in efficiently dewatering and drying various materials, including those generated by sewage treatment plants.

Technological Advancement

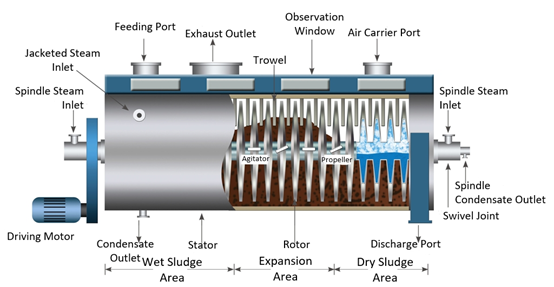

Over the decades, the sludge disc dryer underwent significant technological advancements, enhancing its efficiency, durability, and versatility. Traditional disc dryers comprised three main components: a stationary shell (stator), a rotating disc (rotor), and a drive mechanism. The rotor, featuring a central axis supporting multiple welded discs, was designed to withstand the rigors of the drying process. These discs, made of materials ranging from low-carbon steel to stainless steel or special alloy steel, were equipped with propellers and mixers to facilitate material movement and mixing.

The stator, a cylindrical shell enclosing the rotating discs, featured steam outlets and flange-mounted endplates for easy maintenance and bearing support. The introduction of internal heating systems, such as high-pressure steam, thermal oil, or hot water, further improved the heat transfer efficiency, reducing energy consumption and drying time.

Modern Applications

Today, sludge disc dryers have transcended their initial applications, becoming indispensable in various industries. They are widely used in municipal and industrial wastewater treatment plants, effectively reducing the moisture content of sludge and facilitating its safe disposal or reuse. Beyond sewage sludge, these machines are also employed in fish processing, meat production, brewing, and various industrial drying processes.

Market Leaders and Innovations

TIC Technology Co., Ltd., a subsidiary of TDG Holdings (stock code: 600330), have taken the lead in developing state-of-the-art sludge disc dryers. By integrating international technologies with domestic innovations, TDG TIC has introduced SDK and FDK series disc dryers, capable of handling diverse sludge types from municipal, petrochemical, and industrial sources. These machines feature optimized heat transfer areas, ensuring efficient steam distribution and low energy consumption. Furthermore, their advanced control systems enable precise temperature and oxygen level management, enhancing operational safety and environmental compliance.

Environmental Impact

The widespread adoption of sludge disc dryers has had a profound impact on environmental sustainability. By reducing the moisture content of sludge, these machines significantly decrease the volume and weight of waste, facilitating its transportation, storage, and ultimate disposal. Moreover, the dried sludge can be reused as a soil amendment or an alternative fuel, promoting circular economy principles and minimizing the need for landfilling.

Conclusion

The evolution of sludge disc dryers from a niche technology to a ubiquitous solution in waste management underscores the relentless pursuit of innovation in the environmental sector. As technological advancements continue to shape the landscape of sludge treatment, these machines will play an increasingly vital role in ensuring the safe and sustainable management of industrial and municipal waste. With a focus on energy efficiency, environmental compliance, and resource recovery, the future of sludge disc dryers looks promising, offering a sustainable path forward for waste management worldwide.

As a sludge dryer manufacturer and disc sludge drying solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to tic@tdgtic.com.