BLOG

Efficient Drying Solutions: Unraveling the Wonders of Disc Dryers

Efficient Drying Solutions: Unraveling the Wonders of Disc Dryers

18 September 2023

What is a disc dryer?

A disc dryer, also known as a paddle dryer, is a type of industrial drying equipment used to efficiently remove moisture or liquids from various materials or substances.

The main components of a disc dryer include a series of heated, rotating discs or plates arranged in a stack. These discs are typically made of a heat-resistant material such as stainless steel or carbon steel. The material to be dried is fed onto the heated discs, and as the discs rotate, they come into contact with the material, transferring heat to it indirectly.

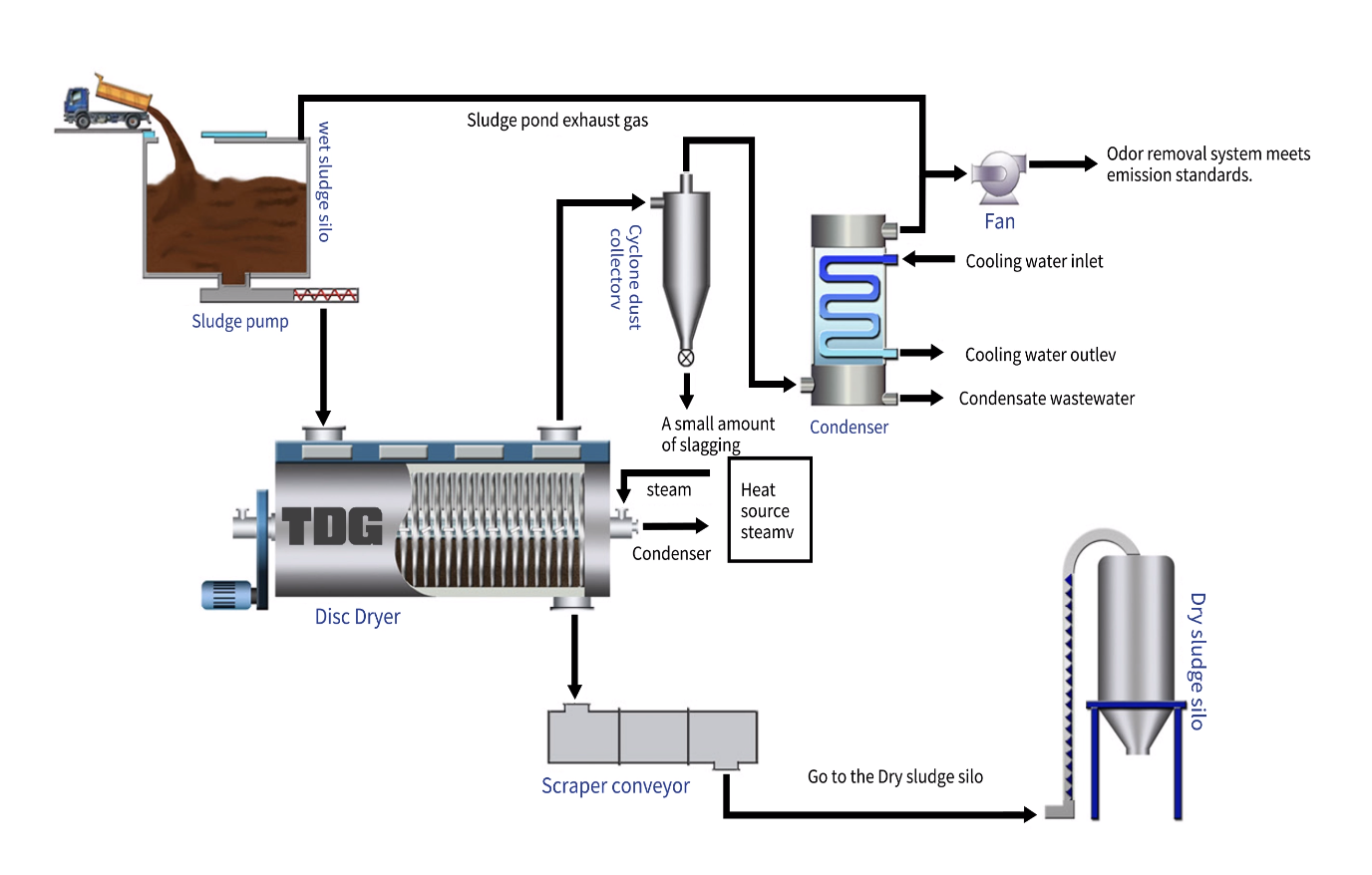

Sludge Drying Solution by Disc Dryer

Drying processes play a pivotal role across various industries, from food production to waste management. One innovative solution that has been making waves is the disc dryer. In this blog, we'll delve into the world of disc dryers, exploring their compact design, efficient use of floor space, and the incredible technology of heated discs for indirect heat transfer.

Compact Design for Space Optimization

Space is a valuable commodity in any production facility, which is why the compact design of disc dryers is a game-changer. These machines are engineered to maximize floor space utilization. Their vertically stacked heated discs allow you to make the most of your available area. Whether you're working in a bustling food processing plant or a compact chemical facility, disc dryers are designed to fit seamlessly into your space.

Heated Discs for Indirect Heat Transfer

One of the core innovations of disc dryers is the use of heated discs for indirect heat transfer. This means that the product being dried doesn't come into direct contact with the heat source. Instead, the heat is transferred indirectly through the discs. This ingenious method minimizes the risk of overheating or damaging your raw materials, ensuring the integrity of your product throughout the drying process.

Efficient Steam Control

Steam control is a critical aspect of effective drying processes, and disc dryers excel in this regard. Operators have precise control over steam temperature and flow, guaranteeing that your materials receive the ideal amount of heat for efficient drying. This level of control is especially important when dealing with delicate or heat-sensitive materials.

Versatility with Various Raw Materials

Disc dryers are versatile machines suitable for a wide range of raw materials. Whether you're drying food products, chemicals, or even sewage sludge, disc dryers can handle the task efficiently. The indirect heating method ensures that the drying process is gentle, preserving the quality of your raw materials.

Producing High-Quality Dry Products

The ultimate goal of any drying process is to produce a high-quality dry product, and disc dryers deliver on this front. With precise steam control, consistent heat transfer, and careful handling of materials, you can expect superior results. Your final product will meet your quality standards consistently.

Conclusion

In conclusion, disc dryers are a compact and efficient solution for a wide range of drying applications. Their innovative design optimizes floor space utilization, while the use of heated discs for indirect heat transfer ensures the safe and efficient drying of various raw materials. Whether you're in the food industry, chemical manufacturing, or waste management, disc dryers offer a cost-effective and space-saving solution for your drying needs.

If you're looking to enhance your drying processes, consider the advantages of disc dryers. For more information or inquiries about how disc dryers can benefit your specific industry, don't hesitate to reach out to us (tic@tdgtic.com). Disc dryers are not just a technology, they're a smart investment in efficiency and quality.