BLOG

Disc Dryer: Compact, Efficient, and Environmentally Friendly Drying Solution

Disc Dryer: Compact, Efficient, and Environmentally Friendly Drying Solution

21 September 2023

Introduction:

Drying processes play a crucial role in various industries, from food production to wastewater treatment. One innovative and efficient solution gaining popularity is the disc dryer. This advanced drying equipment offers a compact design, effective heat transfer, and versatility in handling a wide range of materials. In this blog, we will explore the disc dryer's features, its applications, and how it stands out in terms of sustainability.

Compact Design and Floor Space:

One of the standout features of a disc dryer is its compact design. Unlike traditional drying systems that require extensive floor space, disc dryers are space-efficient. They are designed to maximize heat transfer surface within a limited footprint. This space-saving design is particularly valuable in industries where floor space is at a premium.

Efficient Heat Transfer with Heated Discs:

Disc dryers employ a series of heated discs that rotate and come into contact with the wet material being processed. This direct contact ensures efficient heat transfer, allowing for rapid moisture removal. The heated discs are typically steam heated, which is a reliable and energy-efficient heat source.

Indirect Heat Transfer:

Disc dryers often use indirect heat transfer, where the heating medium, such as steam, does not directly contact the product. This indirect method is ideal for applications requiring gentle drying, as it prevents product contamination and maintains product quality.

Applications in Diverse Industries:

Disc dryers have found applications in a wide range of industries:

Food Industry: Disc dryers are used for drying various food products, including fruits, vegetables, and cereals, while preserving their nutritional value.

Chemical Industry: They are used for drying chemical powders, resins, and pharmaceutical intermediates.

Environmental Engineering: Disc dryers play a crucial role in drying sewage sludge, reducing its volume for more cost-effective disposal.

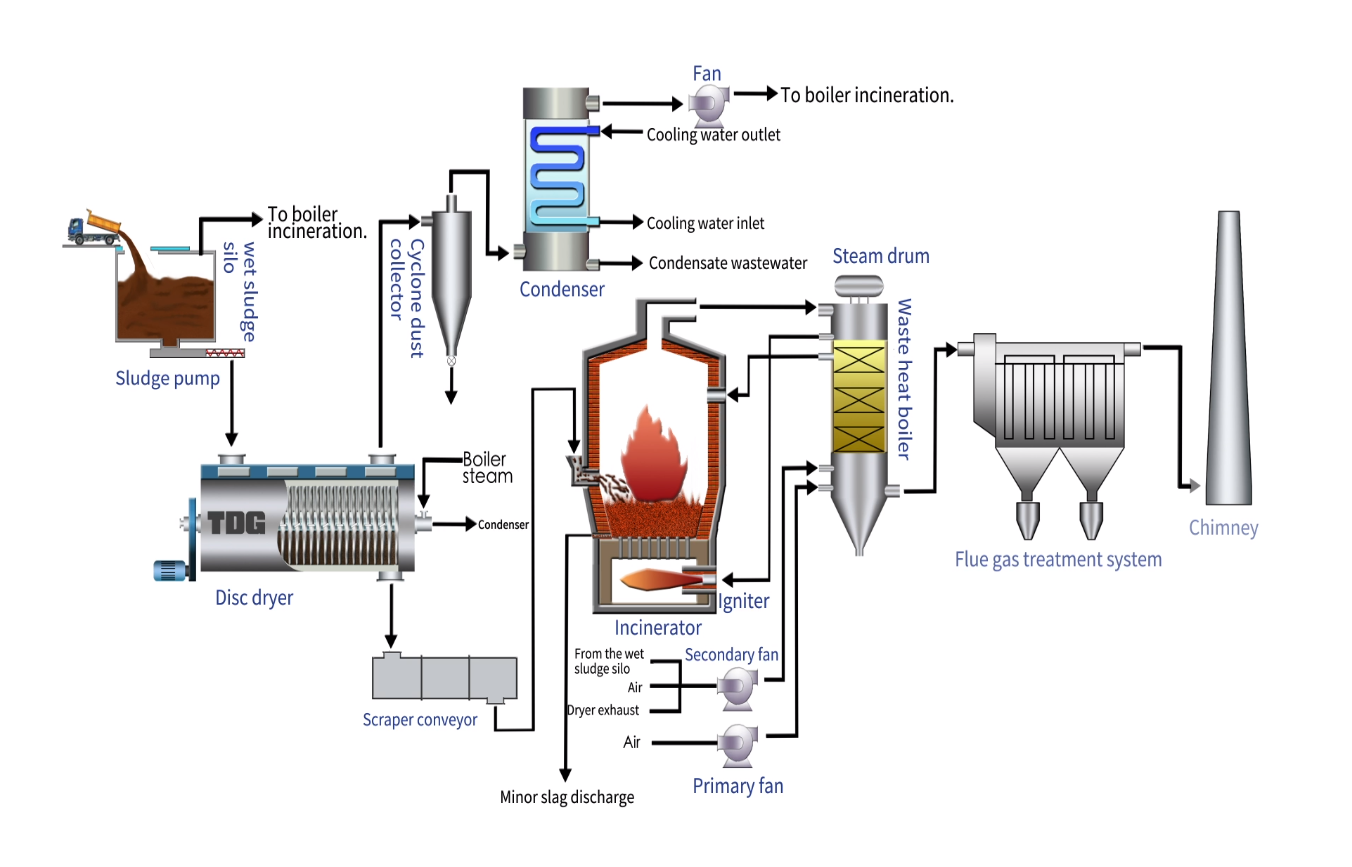

Drying Incineration Process

Mining and Minerals: They are used in the drying of minerals, ores, and metallurgical concentrates.

Sustainable Drying Processes:

Disc dryers contribute to sustainability in several ways:

Energy Efficiency: Their compact design and efficient heat transfer reduce energy consumption compared to traditional drying methods.

Minimal Product Loss: Gentle drying prevents product degradation and loss, ensuring a higher yield of valuable materials.

Reduced Waste: Drying sewage sludge with disc dryers reduces the volume for disposal, making it an environmentally friendly choice.

Versatile Raw Materials: Disc dryers can handle a variety of raw materials, making them versatile and adaptable to different industries.

Conclusion:

The disc dryer is a compact, efficient, and sustainable solution for drying processes across various industries. Its heated discs, indirect heat transfer, and versatility make it a valuable asset for businesses looking to reduce energy consumption, minimize product loss, and contribute to environmentally friendly practices. As industries continue to prioritize sustainability, the disc dryer is poised to play an increasingly essential role in modern manufacturing and wastewater treatment.